views

Formed without an actuator and planned with fewer parts, floating piston valves require less support, lessening their size and cost. Fresher models of the floating piston are of greater, resolving prior issues from past plans.

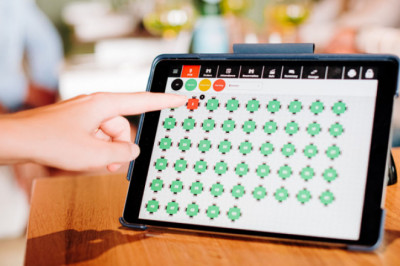

Floating piston valves comprise a strong piston squeezed against a fixed, strong seat that is suspended in a medium with the goal for it to control the stream and seal the valve. Regardless of whether the valve is open or shut, floating pistons are explicitly intended to stay adjusted inside a stream. The lone power utilized on a piston is what the administrator decides to enter. In view of the necessity to utilize this valve physically, there is the dispensed with a factor of an actuator and in its place is one to two solenoid valves.

The floating piston is a fairly oversimplified valve, made out of just five sections, with its seals fabricated to be all around ensured by the plan. The piston’s straightforward plan makes it a strong alternative for high pressing factors, delicate or hard metal seats while expanding the valve's dependability and seat life. Moreover, by killing the actuator, the valve's trustworthiness and life expectancy are enormously improved. Its design is explicitly made to guarantee that liquid pressing factors within the valve will stay adjusted, giving the floating piston valves an expanded life expectancy.

Uses of Floating Piston Valves

The Valves have a wide assortment of likely applications and are genuinely flexible. Its basic plan makes it solid and simple to keep up with. A few uses of piston valves include:

Force and Petrochemical Plants

Substance Processing

Treatment facilities

Compressing Storage Tanks

Cryogenic Fluid Systems

Drug Manufacturing

Applications Requiring Severe Duty, Extremely High Pressures or Temperatures

Applications Requiring Fast Actuation

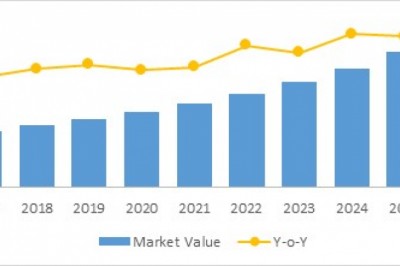

Throughout the long term floating piston valves have been re-designed to improve the soundness of the plan to guarantee its solidness. Likewise, new models are viable with hard or delicate metal seats with a flexible shutting power. At long last, some more current floating piston valves can withstand pressures up to 15,000 psi.

Advantages of Choosing Piston Valves

The straightforwardness of configuration diminishes the intricacy of upkeep

The disposal of a valve stem and an actuator lessen the size and cost of the valve.

It doesn't require many seals; consequently, the support is extraordinarily decreased while having an expanded life expectancy.

The way of the stream is quite often even, thusly, there is a diminished possibility of prompted push loads both during the change from open to shut.

No outlaw discharges

Can withstand high pressing factors