views

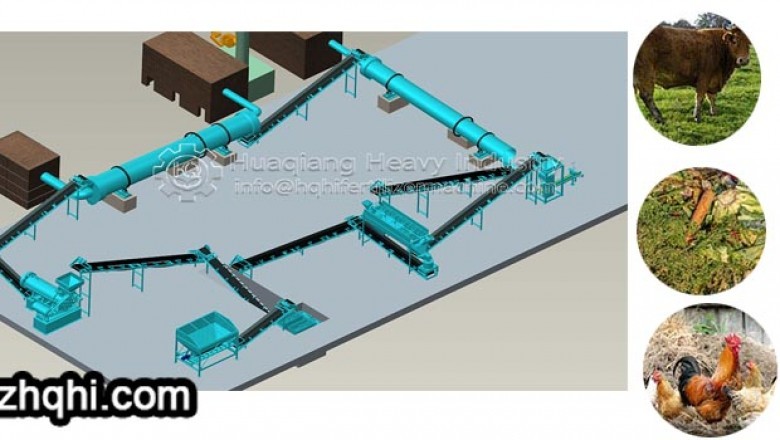

Equipment flow of powdery organic fertilizer production line

The powdery organic fertilizer production process needs four steps: fermentation, crushing, screening and packaging. Therefore, the powdery organic fertilizer production line mainly needs to use: crawler dumper, semi wet material crusher, drum screening machine, packaging scale (can be omitted). Crawler type dumper is also called ground type dumper. It is suitable for use on the ground with a wide area and no obvious pits. With crawler type design, even if the ground is wet and slippery, it will not slip. It can be opened as soon as it is used and can rotate 180 degrees. After fermentation, it needs to be crushed. The main function of the crusher is to crush the rotten large stem into smaller and more uniform particles, so as to avoid the impact of large stem on the normal growth of plant roots in the process of use. At the same time, the organic materials piled up for a long time will also agglomerate.

The crushing equipment of organic fertilizer production line is semi wet material crusher. Because of its wide application range, under certain hardness conditions, the materials with moisture less than 50% can be crushed, so it is also known as the special crusher for organic fertilizer. After crushing, screening and grading are carried out with the help of drum screening machine, so as to further screen out the redundant sundries and the bulk materials that have not been crushed well, and improve the commodity appearance of powdery organic fertilizer. Screened organic materials can be directly sold and pulled out of the factory or packed for transportation. The organic fertilizer production plant cost is hundreds of thousands to millions.