views

What is the optimization work in the process of organic fertilizer production line?

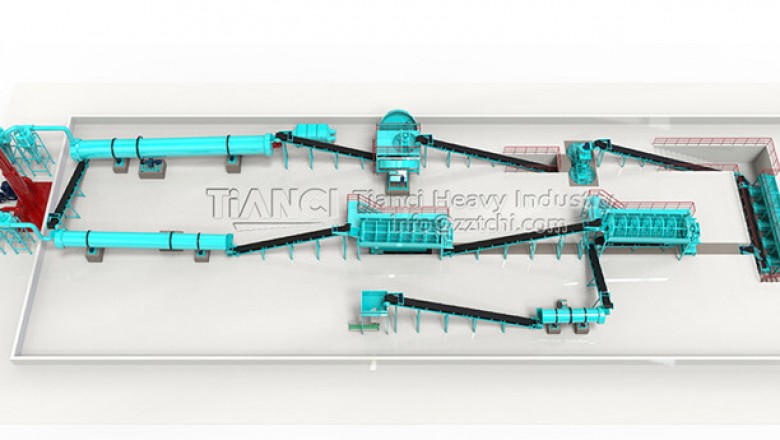

Process optimization of organic fertilizer production line equipment

1. Comminuted part. In view of the diversity of raw materials for users, therefore, our organic fertilizer production line equipment, designed the crushing part. In the process of equipment sales, we found that many users' raw materials are dry chicken manure or pig manure, and some users even mixed some other materials to reduce the production cost of organic fertilizer. As we know, materials with too large diameter can not be granulated directly. Therefore, before granulation, we need to crush the raw materials to achieve the effect of granulation, and then the crushed materials can enter the granulator. Of course, users with enough fineness of materials can omit this link when designing organic fertilizer production machine.

2. Drying section

The premise of granulation is that the humidity of materials should be controlled below 25%. Therefore, for some raw materials with initial humidity above 25%, they should first enter the drying process, and then enter the granulator after the drying materials reach the corresponding humidity. Of course, users with enough humidity of materials can omit this process in the design of organic fertilizer equipment.

3. Granulator

The core of the equipment of organic fertilizer production line is granulation, so the granulator is indispensable. The model selection of granulator machine for fertilizer is determined according to the hourly output of users. We suggest that you choose Huaqiang new type organic fertilizer granulator as the core part of the whole organic fertilizer production line.

4. Other parts

After granulation, it is transported to the organic fertilizer throwing and shaping machine by belt conveyor to shape the granules, which have reached the spherical shape. For the users who have demand, we will design a packaging link to directly package the finished products, which has realized the automatic production of the whole production line equipment.

Fertilizer machine manufacturers are not easy to find, please come to Zhengzhou Tianci Heavy Industry Machinery Ltd!!! Zhengzhou Tianci Heavy Industry Machinery Ltd specializes in the production of fermentation compost windrow turner, organic fertilizer granulator, fertilizer mixer machine, fertilizer crusher and other organic fertilizer machines. We also provide a complete set of organic fertilizer production process, npk fertilizer manufacturing process, bio organic fertilizer production process, BB fertilizer production equipment. We have been stepping forward the pace of machine progress, hoping to use the best fertilizer equipment to feed back our users!