views

Overview

Artificial intelligence has transformed the way people operate, and there is no doubt about this. Right from Netflix recommendations, advertising to healthcare, AI enhances people’s daily lives directly by offering a customized, efficient, and fast experience. Not only this, artificial intelligence appears to be the answer, as well as promises to revolutionize the manufacturing sector. AI is an amazing present. With constant shifts in consumer expectations and needs, most industries rely on AI to increase efficiency to better cater to customer demands.

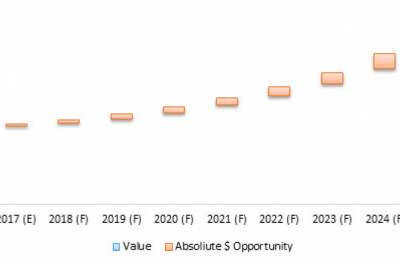

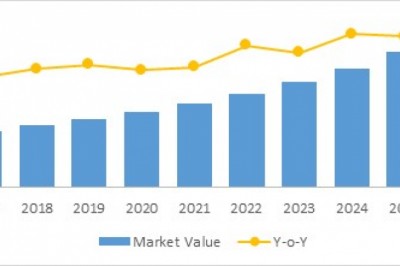

The take of global artificial intelligence (AI) in the manufacturing market recorded by Market Research Future reveals that the market can hit 47.09% to the net worth with USD 14.77 billion by 2027 amid the long-term impact of COVID-19. The years of growth is calculated to be from 2020-2027.

Top Grossing Factors

The global artificial intelligence in the manufacturing market has gathered pace in its growth amid COVID-19 breakthrough with rapidly evolving industrial automation and IoT, at present. Artificial intelligence is one of the highest-growing technologies in recent years. Artificial intelligence is allied with human intelligence with similar characteristics such as understanding, problem-solving, reasoning, language, and learning. An amalgamation of AI in the manufacturing industry offers a safer operational environment, which further assists in enhancing the quality and quantity of production.

One of the main factors, such as the exponential growth in digital data, is motivating the growth of artificial intelligence (AI) in the manufacturing market. It is approximated that by the year 2020, around 1.7 megabytes of new data will be created every second. It is further approximate to expand at 40% over the next ten years. Such growth is attributed to the escalating adoption of big data technologies and IoT devices along with the ascend in popularity of cloud platforms among enterprises. All these factors are cheering the adoption of artificial intelligence solutions among the manufacturers to process the data and extract actionable insights.

Furthermore, the factor of enhancement in automation in the manufacturing industry and the rise in demand for big data integration boost the escalation of AI in Manufacturing Market Size . With this, prevalent usage of machine vision cameras in manufacturing applications, such as material movement, machinery inspection, quality control, and field service, is also to drive the growth of artificial intelligence in the manufacturing market for the forecast period.

Pivotal Role of AI in the Manufacturing Sector

Artificial intelligence is widely used in the manufacturing sector for the following reasons,

Round the Clock Production- Human beings being biological organisms, need regular maintenance such as sleep and food. For production facilities to continue working 24/7, it is essential to introduce shifts, utilizing three workers every 24 hours. On the contrary, robots neither feel hungry nor get tired and can work 24/7. This, in turn, expands the production capabilities that are essential to cater to the needs of the customers worldwide. Besides, robots are highly efficient in most areas like the assembly line and the packing & picking departments. The best part, robots can help to cut down turn-round times in most parts of business operations.

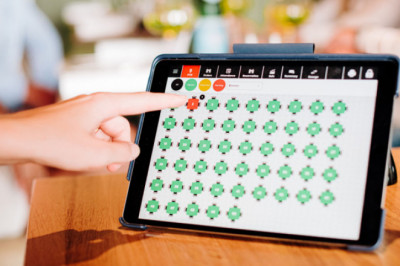

Quality Control- Artificial intelligence is immensely useful to perform predictive maintenance on equipment and machinery. Using sensors for operating conditions and tracking performance, machines can learn to predict failures and malfunctions and take action to remedy these before they occur. It will, in turn, lead to faster feedback, assisting companies in eradicating unplanned downtimes. A sensor can also help in detecting microscopic defects, scan the same at resolutions beyond human vision, thus enhancing productivity and increasing the number of goods that pass quality control. Artificial intelligence helps in speeding up most routine processes and improving accuracy to a great extent. This will prevent the need for in-process inspection and quality control by human beings that is often fallible and time-consuming.

Safety- Humans are fallible and susceptible to making errors, particularly when they are distracted or tired. Accidents and errors occur in the factory, processing environment, or construction area, a tendency that can be eradicated by robotic assistance and AI. Remote access control indicates cutting down human resources, particularly when the work needs superhuman effort or is dangerous. Regular working environments too will reduce industrial accidents and result in an improvement in safety overall. Further, higher advanced sensory equipment integrated with the IIoT devices helps make the installation of barriers and safety guards a more effective and simpler measure for protecting human lives.

Get a Free Sample @

https://www.marketresearchfuture.com/sample_request/7745

Optimize Supply Change- When artificial intelligence is used in the supply chain, there is increased data and transparency. It is used for improving customer service and manufacturing processes. Data from several devices are gathered and analyzed in real-time for an in-depth insight such as a possible challenge. The manufacturer then can take informed industry-related decisions. Artificial intelligence helps minimize time and cost that may be invested in shipping and warehousing during a mishap. AI solutions and tools can help schedule factory activities, supply and demand gaps, and avoid under or over production.

Improved Generative-Design Process- Through AI, manufacturers can make improved means to design their products. The designer with generative designs can easily input product details. These details comprise the material type, time, budget, and appropriate production methods. The designer can also input every possible constraint. The details using an artificial intelligence algorithm can be processed for meeting a list of probable product options. An appropriate solution will then be tested to suffice manufacturing conditions. A key factor that makes the generative design have the upper hand is it eliminates the human bias design option. It also proposes more ideal performance demands.

Real-time Monitoring- This is a key perk of AI in manufacturing because it offers a detailed picture of inefficiencies that are taking place in the manufacturing process and what causes the bottleneck. The capability to pinpoint the exact process that needs improvement enables businesses to promptly address the issue, resulting in cost and time savings.

Customer Management- The applications of AI for manufacturing boost productivity, business performance, and sales. The smart artificial intelligence apps for manufacturing can right away understand customer problems and offer personalized solutions. AI solutions and service in customer services offers a plethora of benefits namely,

(a) Make an informed decision through customer data

(b) Improved relations using customer relationship management (CRM)

(c) Personalized experience

(d) Quick response time

Detect Errors- A manufacturer can use an automated visual inspection tool to look for defects on the production line. Different visual inspection equipment like machine vision cameras can detect faults accurately and quickly than human eyes. For instance, a visual inspection camera can find a flaw easily in a complex, small item such as a mobile phone. The attached artificial intelligence systems will alert workers regarding the flaw before this reaches an unhappy consumer.

Lower Operational Costs- Most companies are considering introducing artificial intelligence into the manufacturing sector with trepidation, as this needs a massive amount of investment. The ROI, on the contrary, is essential and increases with time. The moment intelligent machines start taking over the day-to-day activities of factory floors, a business will benefit due to considerably reduced operations costs, with predictive maintenance assisting additionally for reducing machine downtime. Consumers these days are boosting their need for customized, personalized, and unique products while continuing to expect the best value. Following advances such as IIoT connected devices and 3D printing, it has become cheaper and simpler to meet these needs and utilize augmented or virtual reality techniques, indicating that the entire production process will be cost-effective. Integrating CAD and machine learning indicates that the system can be designed and tested in virtual models before putting them into production, reducing the trial-and-error machine testing cost.

Quick Decision Making- As IIoT is coupled with AR or VR and cloud computing, organizations can share simulations, exchange critical information in real-time, or confer on the production activity, regardless of geographical location. The data collected from beacons and sensors help determine consumer activity, enabling organizations to anticipate future needs and make quick decisions on production and speed up the exchange between suppliers and manufacturers.

With all these perks and much more, it will not be an exaggeration to state that artificial intelligence is indeed the future of the manufacturing sector.

AI in manufacturing Market Key Players:

Market Research Future has identified following key players in the market—Nvidia Corporation, Intel, Inc., IBM Corporation, Siemens AG, General Electric company, Google, Inc., Microsoft Corporation, Amazon Web Services, Bosch, Rockwell Automation, Cisco Systems, SAP SE, Foxconn, and others.

Browse Complete Report @

https://www.marketresearchfuture.com/reports/artificial-intelligence-ai-in-manufacturing-market-7745

AI in Manufacturing Market Research Report: Information by Technology (Hall Effect, Magneto Resistive, Variable Reluctance), By Application (Automotive, Industrial, Aerospace & Defense, Consumer Electronics) and Region (North America, Europe, Asia-Pacific, Middle East & Africa, and South America)—Forecast till 2030

> Trending Reports

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact:

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Email: sales@marketresearchfuture.com

Website: https://www.marketresearchfuture.com

Follow Us- https://www.linkedin.com/showcase/ict-mrfr/