views

Pressure Sensors for Medical Ventilators

In numerous applications and businesses, it is entirely expected to run over the gamble of exorbitant strain, or overpressure, inside the pneumatic or water powered organization of gear, particularly in offices with a serious level of computerization. On the off chance that this peculiarity isn't controlled as expected, it might make super durable harm hardware and creation lines which is the reason pressure sensors are regularly utilized as some type of security in a few tasks like modern, clinical, bioprocessing, and drug.

burst pressure

ESCP-MIS1-headerNevertheless, pressure transducers pressure indicating film are not generally ready to deal with outrageous degrees of strain. To endure outrageous tensions, specialists and creators have characterized pressure evaluations that can portray the circumstances a strain part can endure without influencing its functional exhibition. These are separated into:

appraised pressure

The greatest tension that the producer doles out as the ideal strain at which a gadget will work appropriately is typically illustrated as evaluated pressure. An overpressure esteem is a condition where the tension transducer can endure unreasonable strain without influencing execution or compromising ensuing estimations. Frequently overpressure is confused with burst pressure, which is characterized as the greatest tension that can be applied without genuinely harming the body of the detecting part.

overpressure

For instance, on the off chance that a tension sensor has 2 bar evaluated pressure, 5x overpressure, and 10x burst pressure, this implies that the sensor can gauge pressures up to 2 bar, it can endure overpressures up to 10 bar without being harmed, and assuming the strain arrives at 20 bar the sensor fixing will explode. From 10 to 20 bar, the sensor doesn't explode however it is harmed and won't work true to form.

What can cause overpressure?

Various variables can set off overpressure, including Fujifilm prescale unexpectedly expanded heat, inspire, a broken strain controller, process synchronization, or a combination of this multitude of elements. These causes are normal in modern applications where there are solenoids, radiating siphons, controllers and valves.

How capacitive sensors can forestall disastrous disappointments because of overpressure

Because of their plan and estimation standard, MEMS capacitive tension sensors can deal with up to 100x overpressure, creating them the main accessible sensor innovation in the market that can endure high overpressure.

The overpressure resilience alongside the astounding exactness and all out blunder band determination make capacitive sensors ideal for any application that utilizations siphons or valves, particularly in computerization hardware, where overpressure is often capable.

Prior to choosing a sensor, the greatest tension worth required for the application ought to be thought about. Grasping the upsides of every innovation, the elements of their framework, the restrictions of the sensor, and the different ways it very well may be applied are critical to build efficiency and lower upkeep costs.

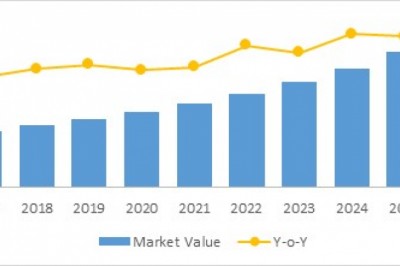

In the accompanying figure, you can see an application illustration of the overpressure execution of a 10 bar outright adjusted sensor from ES Systems. The sensor's most extreme anticipated working strain (MEOP) is 10 bar. The sensor is estimated at a reference tension of 9.3 bar outright and afterward compressed at the accompanying strain ventures as found in the chart underneath.