views

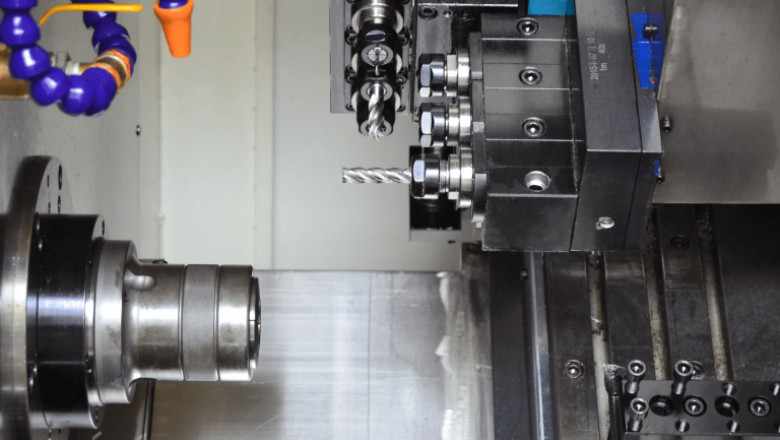

Personal computer Numerical Control (CNC) machinery is developing very popular, and also it is so easy to find out exactly why. This high tech production technique eliminates a lot of the obstacles which stop designers by producing the merchandise of the dreams of theirs. Among the best benefits of utilizing CNC machinery is the fact that you are able to make really advanced parts with a significant level of reliability which just is not doable using traditional techniques of previous times.

Regardless of whether you are seeking to produce probably the most good components or maybe you've an option for an intricate as well as revolutionary brand new device, you need to really contemplate utilizing CNC machinery for the next project of yours.

The Role of CNC Machinery in Manufacturing

A CNC printer utilizes particular application to manage cutting other manufacturing instruments or tools. To program the device, a coder or even competent engineer uploads an electronic type of the portion or perhaps item from a computer aided style (CAD) process. Next, utilizing a CNC coding words known as G Code, the coder provides the printer detailed producing directions such as:

Where you can reduce or even accomplish specific actions;

Exactly how quickly to do every action;

What areas of the machinery should co-ordinate to do a task.

The speed at what raw materials become given into the device or even work station; And much more.

This varies from typical machinery in that the whole procedure is programmed on a laptop in advance and also done remotely by advanced devices.

By comparison, standard machinery is generally done by a group of operators or engineers who immediately oversee specific devices which do particular things in phases. For instance, a component might proceed through lathe, grinder, and a mill, each one of that is operated by diverse experts. It is a more time consuming as well as labor intensive procedure. This's among the primary reasons CNC machinery is participating in a much better part in contemporary production. CNC machinery is a dazzling, stylish means to fix most complicated engineering & producing obstacles.

Utilizing CNC Machinery on the Shop Floor

Five Major Benefits of Using CNC Machinery Among the primary reasons CNC machinery is very preferred is since it allows merchandise designers to produce more complicated parts. These models are particularly helpful for producing areas with perspectives which are hard to calculate as well as lower yourself. But you will find numerous additional benefits of utilizing CNC machinery in the contemporary production sector, these kinds of as:

#1: Eliminating Inconsistencies and human Error If you create a portion or maybe item by hand or perhaps utilizing traditional solutions, you cannot realize exactly the same level of accuracy and consistency as you are able to utilizing CNC machinery. CNC models employ layout program, detailed unit recommendations, along with fine tuned accuracy programs to create as well as replicate several areas which are practically the same (with an average deviation of under 0.020mm - sometimes as few as 0.003mm). Actually probably the most innovative standard devices cannot identical the outcomes.

This implies that you will obtain an incredibly even end product. In industries in which tall uniformity is important (such as the automobile, aerospace, dentistry, as well as health-related industries), this's a significant edge. It is likewise a must have for businesses creating complicated electronics or machines that need various components to fit together completely. Almost any small deviation of dimension, form, or maybe feel might result in the last item to malfunction. With CNC machinery, you are able to generate nearly every item and replicate it again and again - still in case it is unbelievably complicated as well as thorough.

#2: Speeding up the Manufacturing Process Unlike conventional machinery or manual manufacturing, and that usually requires an engineer to work and monitor the procedure, CNC machinery is a far more hands off approach. Nearly all CNC machines run instantly with no immediate control or input from designers. The device is prepared to go the moment it gets the instructions of its from the manufacturer and the computer materials the raw materials. This implies that you are able to fabricate components faster, as there is simply no mechanical labor or maybe too much downtime needed. Several devices may even use 24/7.

#3: Using Fewer Resources Among the rewards of utilizing CNC machinery is the fact that you will capitalize on materials at each phase of the product development process. In the first phases, you simply have to have an experienced programmer or engineer to make an electronic type of the layout as well as system the device. When it is some time to produce the item, the CNC printer is basically self sufficient (but could be administered by an operator). It is able to additionally be programmed to greatly reduce waste and just apply that much raw content as essential.

#4: Reducing Manufacturing Costs After a while Using far fewer resources & labor additionally results in cost savings. If you save the resources of yours, you are able to often reinvest everything you kept into manufacturing much more components or maybe you are able to decrease the list price of your respective end result to obtain a competitive edge and entice clients. And even, whenever you delegate your product advancement to a full service CNC machinery provider, you will additionally save money on overhead expenses. The maker is liable for buying the machinery and software licenses, replacing or repairing devices and cutting equipment, and employing staff members to oversee the meditation process. You will just purchase the last outcomes.

#5: Scaling Up Production One last benefit of utilizing CNC machinery is it provides you with much more producing alternatives. You are able to begin with a small run of high quality pieces. Eventually, in case the need for the product of yours is rather high or maybe you have to swiftly scale up to corner the sector, it is super easy to fabricate further areas with a CNC machine. Furthermore, the quality as well as consistency of your supplements stay precisely the exact same whether you are creating a few components or even thousands. You are able to determine just how lots of areas you require at any time and lower extra inventory.

It is additionally really simple to create an element once again, even decades after you initially manufactured it. So long as you've the style kept properly in the CNC program, you are able to get back to it as frequently as you would want.

With the amount of benefits of utilizing CNC machinery for production, it is an alternative that each product designer as well as business proprietor must seriously think about.

Utilizing CNC Machinery

Must you Use CNC Machinery?

For the majority of tasks, the rewards of utilizing CNC machinery are crystal clear. When you are searching for a producing technique which can provide excellent electronics fast with a significant level of precision and accuracy, CNC machinery is the apparent option. It is cost-effective, reliable, and efficient.

It is likewise the perfect option for industries which demand constant products or parts that should be performed by a tight deadline. For instance, several industries which pretty much solely utilize CNC machinery for producing are:

Medical and dental unit companies;

Oceanography; and telecommunications

The other and military federal organizations;

Nevertheless, while you can find numerous benefits of utilizing CNC machinery, it is not always the best option for each task. This particular technique could be costlier compared to many other production choices, based on just how complicated the product of yours is or maybe the number of areas you have to construct. For example, in case you simply have to produce a dozen easy common components, then simply advanced CNC machinery might be extreme. Fast casting, three dimensional printing, along with various other little scale production techniques are usually much better options in this instance.

To determine whether CNC machinery is appropriate for the project of yours, you need to get in contact with a seasoned staff of producing designers who'll take you step the advantages and disadvantages of this particular product. They are going to take into account the manufacturing budget of yours, the intricacy of the portion or maybe product you wish to generate, the number of devices you will need, and just how quick you would love them created. With this particular customized, alternative method, you will receive the best from the production operation.

The full name of HJY Hardware is Shenzhen HongJingYuan Hardware and Plastic Products Co., Ltd. We were established in 1996 and officially registered in 2022. In these 20+ years, we are in our motherland: China, and are the partner of many leading companies. If you ask China’s leading companies for news from us, most companies will give us affirmation, but this does not mean that we are not doing well in the world. We also have very deep and long-term cooperation with many European and American companies. As a CNC machining service provider with a history of more than 20 years, we have provided unique customized CNC machining services to countless companies at home and abroad. We have produced countless precision CNC machining parts.

Contact

- Email Us:hjy@hongjingyuan.com

- Call Us: +86 136 0255 0692