views

What kind of equipment is needed for a production line with an annual output of 50000 tons of pig manure?

First of all, the pig manure organic fertilizer production process should have fermentation equipment, that is, the tipping machine, tipping machine and fermentation bacteria agent of pig manure organic fertilizer.

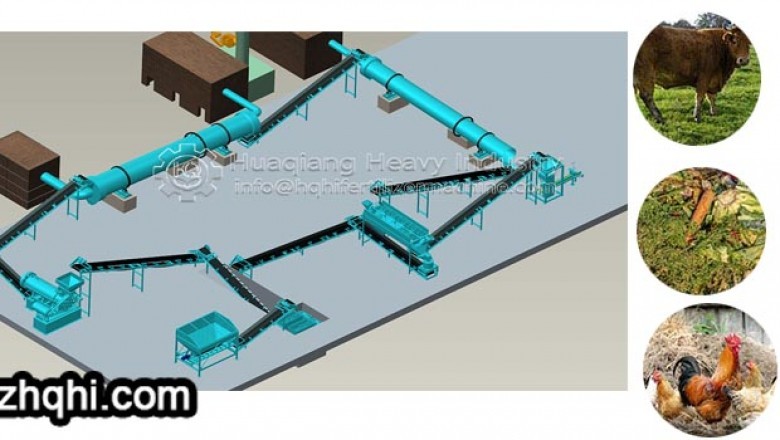

The fermented pig manure organic fertilizer is transported by forklift truck to the semi-finished product warehouse, and then to the pig manure organic fertilizer production line for full automatic production line production. During the organic fertilizer production line, it includes the process of fermentation compost windrow turner, crusher, mixer, fertilizer granulator, dryer, cooler, screening machine, coating machine, packaging machine, conveyor and other equipment

The technology of the project comes from the research results of Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd., which forms the method and technology integration of aerobic composting of microbial agents to ferment animal manure and produce organic fertilizer.

The technology uses livestock manure, crop straw and other agricultural organic wastes to produce organic fertilizer through biological treatment. It has innovation in biological treatment. It uses bacteria, actinomycetes, lactic acid, yeast and other strains to treat livestock and poultry manure, crop straw and other agricultural organic wastes, and improves the nutrient content of livestock manure, crop straw and other agricultural organic wastes Effective, promote crop yield and income.

There are two steps to process commercial organic fertilizer in the organic fertilizer production line: early fermentation and treatment part and deep processing granulation part. Organic fertilizer equipment needs fermentation compost windrow turner, crusher, mixer, fertilizer granulator, dryer, cooler, screening machine, coating machine, packaging machine, conveyor and other equipment. Organic fertilizer production plant cost about 250000 yuan.