views

What is the whole equipment of organic fertilizer production line?

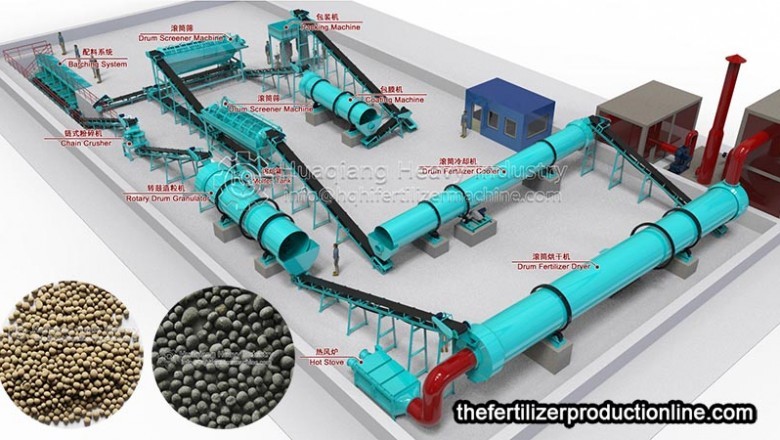

Organic fertilizer production line includes: tipper, also known as fermentation machine, pulverizer, granulator, dryer, sifter, etc. if necessary, automatic packaging machine should be prepared. In fact, these equipment have different preparation parameters and specifications. Of course, the price is also different. We can determine it according to your specific situation According to your needs to customize different equipment.

The complete set of organic fertilizer production machine includes:

1. Raw material stacking and fermentation equipment tank type tipper and ground dumper. The new design of one machine with multiple slots can effectively save space and equipment investment funds. To provide the overall solution for the construction of bio organic fertilizer plant, and to generate the maximum economic benefits with the minimum investment.

2. The new type of dry and wet material crusher vertical and horizontal, the internal structure of chain and hammer.

3. Mixing mixer - including vertical mixer, horizontal mixer, double shaft strong mixer, drum mixer, etc. The internal mixing structure is divided into paddle type and screw type. According to the characteristics of materials, the appropriate mixing structure was designed. The outlet is designed as cylinder control and baffle control.

4. Special granulator for organic fertilizer - disc granulator, new wet granulator, throwing round machine, drum granulator, coating machine, etc. According to the characteristics of raw materials, choose the appropriate granulator. Huaqiang new granulator breaks through the conventional granulation process of organic materials in production of organic fertilizer. Some raw materials need not be reformed before granulation. After the raw materials are crushed, they can be directly mixed to produce spherical particles, which can save a lot of energy.

5. Drum dryer - also known as rotary dryer, bio organic fertilizer dryer.

6. Cooler - similar to dryer in shape, but different in material and performance. The main engine of dryer is made of boiler steel, and the host of cooler is made of carbon steel plate.

7. Screening machines - including drum type and vibrating type. Screening machine is divided into three-stage screen, two-stage screen and so on.

8. The shape of the coating machine is similar to that of the dryer and cooler, but the internal structure is quite different. Stainless steel plate or polypropylene lining is used inside the coating machine. The whole machine includes the powder feeder and oil pump.

9. Automatic metering and packaging machine - including spiral and DC, single head and double head, made of stainless steel and carbon steel, customized according to the actual needs of customers.

10. Conveying equipment - including belt conveyor, screw conveyor, bucket elevator, etc.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. mainly produces 1-200000 tons of organic manure production line, npk fertilizer production line, bio organic fertilizer production line, BB fertilizer complete equipment, rotary drum granulator, double roller granulator, organic fertilizer granulation machine and other fertilizer equipment. Zhengzhou Huaqiang fertilizer equipment has been developing and innovating for many years. In the future, on the road of enterprise development, it adheres to the development and scientific concept, meets difficulties with high-quality service, and strives for perfection.