views

What are the production processes of organic fertilizer production machines

Organic fertilizer production machine needs to ferment before producing organic fertilizer. The fermentation process takes about 45-60 days. In this process, it needs to increase the temperature first to eliminate pathogenic pathogens and some harmful microorganisms in plants, because these products have certain harm to plants, and the metabolites are also unstable, which is not easy to be absorbed by plants. The cooling period in the later stage is short In this process, a large number of metabolites beneficial to plant growth and absorption are produced.

Heating stage of organic fertilizer production line equipment: in the initial stage of composting, the microorganisms in composting are mainly mesophilic and aerobic. They start the fermentation process of composting, decompose easily decomposing organic substances under aerobic conditions, and produce a lot of heat. They continuously increase the composting temperature, from about 20 ℃ to 40 ℃, and reach the mesophilic stage.

High temperature stage of organic fertilizer production line equipment: in the high temperature stage, thermophilic actinomycetes and thermophilic fungi become the main species. They strongly decompose the complex organic matter in compost and accumulate heat. Composting temperature rises to 60-70 ℃, even up to 80 ℃. Then most of the thermophilic microorganisms died or went into dormancy.

Cooling stage of organic fertilizer equipment production line: when the high temperature stage lasts for a certain period of time, most of cellulose, hemicellulose and pectin have been decomposed, leaving complex components and newly formed humus that are difficult to decompose, the activity of microorganisms is weakened, and the temperature gradually decreases. When the temperature dropped below 40 ℃, mesophilic microorganisms became the dominant species. fertilizer machine manufacturers

Composting stage of organic fertilizer production line: after composting, the volume of compost shrinks and the temperature of compost drops to slightly higher than the air temperature. At this time, the compost should be compacted to cause anaerobic state and weaken the mineralization of organic matter, which is conducive to fertilizer conservation.

The above are the processes that the organic fertilizer equipment needs to go through in producing high-quality organic fertilizer. The death, replacement and material transformation of various organisms and microorganisms in the composting process are all carried out at the same time. No matter from the perspective of thermodynamics, biology or material transformation, these reactions can not be completed in such a short time as a few days or more, which is why even all kinds of reactions can not be completed in such a short time Under the premise of good control of temperature, humidity, moisture and microorganism, composting still needs 45-60 days.

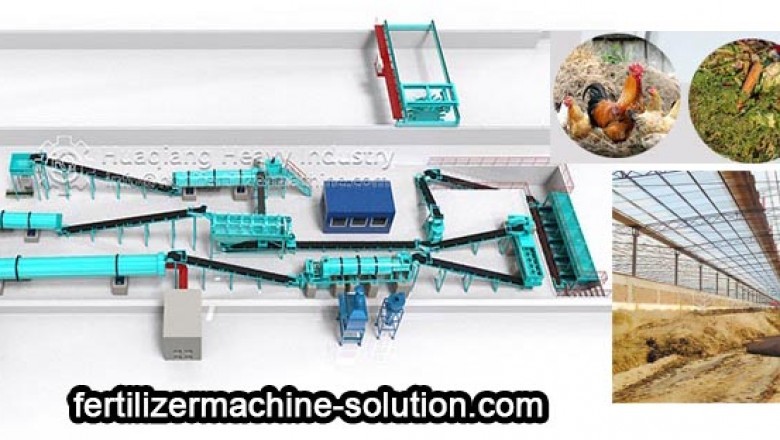

There are two steps to process commercial organic fertilizer in the organic fertilizer production line: early fermentation and treatment part and deep processing granulation part. Organic fertilizer equipment needs fermentation compost windrow turner, crusher, mixer, granulator machine for fertilizer, dryer, cooler, screening machine, coating machine, packaging machine, conveyor and other equipment. Organic fertilizer production plant cost about 250000 yuan.