views

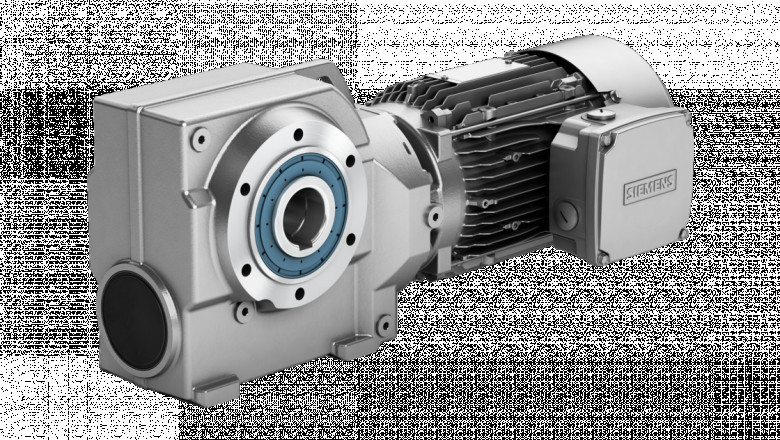

Geared motor, a variation of electric motor, consists of two main parts: the rotor and stator. In its simplest form, it's nothing but a rotating electromagnet. Part of the rotor is a permanent magnet, and part of it is an electromagnet. The function of each part varies depending on how it is constructed.

Different Types of Geared motors

Several gear motors exist, each having different gear ratios, speed capabilities, and torque ratings. Therefore, it is essential to determine the best motor geared for your application before purchasing one. This article will summarize the various geared motors available and discuss selecting the right one for your project.

1. Planetary geared motors

These have a high power-to-weight ratio, making them ideal for tasks where speed is critical. Planetary geared motors can turn heavy loads at high speeds.

Application: Material handling, machine tool drives, etc.

2. Bevel Helical Gearing Motors

The bevel helical geared motor is the most common type of geared motor. It consists of two gears that mesh at a 60-degree angle, resulting in very high torque capability.

Application: Any application that requires high power and speed is a good candidate for a bevel helical geared motor.

3. Spur Gearing Motors

Spur geared motors are most commonly used in small electric clocks and doorbells, but they can also be found in factory automation and small robotics projects. This type of motor consists of a single spiral gearbox on a shaft.

Application: For applications that require low speed and high torque, spur geared motors are a great option. They can also be used for intermittent duty cycles.

4. Internal Gear Motors

Internal gear motors are used when very high torque is required in minimal space. This type of motor has gears enclosed inside the motor housing.

Application: Internal gear motors are great options for small robotic and factory automation projects. They also work well as a rotary actuators.

5. Harmonic gear motors

These small geared motors are similar in look and function to a planetary geared motor, but they are usually only found in large electric clocks that require a very smooth operation.

Application: Harmonic gear motors are typically only used in large clocks and timers.

6. Right Angle Gear Motors

Right angle gearbox motors are externally similar to an essential bevel helical geared motor, but they have an offset output shaft that allows 90-degree turning.

Application: Right angle gear motors will turn loads at a 90-degree gearbox to the output shaft. Typically, they are employed in conveyor systems to rotate the cargo as it moves.

7. Worm and Wheel Geared Motors

The worm and wheel motor is one of the simplest geared motors. It consists of only two gears: a worm gear and a wheel gear. The worm gear has a square shaft driven by the motor, and the wheel gear meshes with the worm gear to create rotational motion.

Application: Worm and wheel geared motors can be used in many small robotic projects due to their simplicity. They are also commonly found in clocks, timers, and other timing projects.

Conclusion

When trying to pick the suitable motor for your particular application, it's helpful to think about the different precision gearbox types and their unique applications.

Summary: Here, we have discussed different types of geared motors and their applications.

Resource Box: Power Ace India is one of India's largest manufacturers and exporters of Right Angle, 90 Degree, and Precision Gearboxes.