views

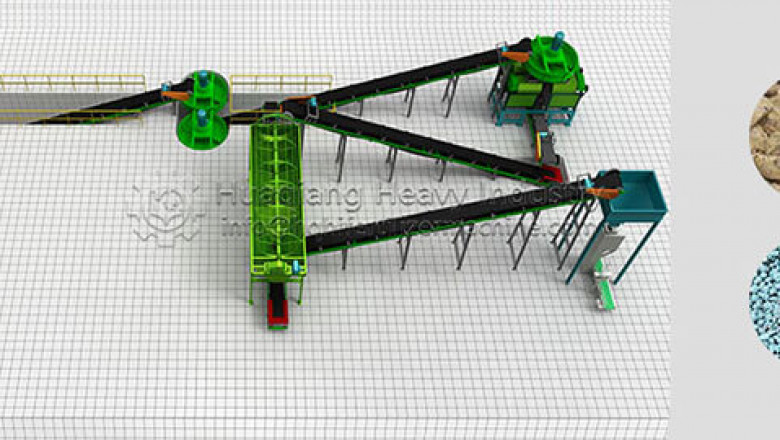

Principle and structure composition of double roller granulator

The principle of double roller granulator: dry material agglomerates into compact and hard block (cake material) under the action of pressure, which is called extrusion process; The cake material is broken and sieved to become granular material, which is called granulation process. The function of extrusion is to squeeze out the air between particles, and to make the distance between particles close enough to produce attractive forces such as van der Waals force, adsorption force, crystal bridge and embedded connection. The particle strength of extrusion granulation mainly depends on the force between molecules.

Structure composition of double roller granulator

The double roller granulator is mainly composed of movable roller device, fixed roller device, pressing and adjusting device and driving device

1. After welding and removing the stress, the matching surface is processed and formed in one time, with high assembly accuracy and smooth operation of the fertilizer granulation machine;

2. The driving device and fixed roller are driven by chain, which can ensure accurate average transmission ratio and high transmission power;

3. The movable roller device is equipped with a spring adjusting device, which can automatically adjust the distance between two sticks in case of unformed hard objects, so as to avoid damaging the equipment.