views

Preparation steps of chicken manure organic fertilizer production

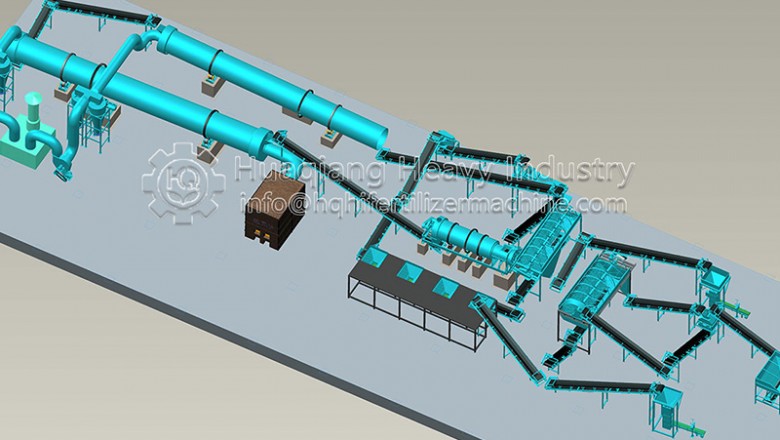

The production of manure from livestock and poultry can be divided into static processing and dynamic processing. Generally, our small enterprises use static processing method to produce organic fertilizer, which is simple, easy to operate, less investment and suitable for our small enterprises( Note: the production of organic fertilizer requires not only the preparation of site, but also the purchase of organic fertilizer production machine. It is suggested that the preparation and purchase should be carried out at the same time). In this process, the following preparations are needed:

(1) Preparation of chicken manure and accessories

Choose a flat ground, no water, about 30 square meters of open space, the chicken manure and accessories are stacked separately. Generally, granular or powdery wheat bran and peanut shell powder are used as the main auxiliary materials. If corn straw and cotton orange stalk are used as auxiliary materials, they should be cut into 5-10 cm length first. Too long will make it inconvenient to stir. The purpose of adding excipients is to adjust the water content and C / N ratio of chicken manure, and increase the air permeability of fermentation products.

(2) Operation steps

Spread the bacteria evenly on the prepared chicken manure and stir evenly. Fermentation of chicken manure requires 3-5kg of enzyme bacteria. In the mixing process of fertilizer production machine, the water content of chicken manure should be adjusted to about 60%, that is, grasp a handful of chicken manure in your hand, hold it tightly into a ball, and water can be seen between your fingers, but not dripping. Release the hand, gently touch to spread, so that the water content can be. If the water content is too high, we should sprinkle wheat bran, corn straw and other accessories on the chicken manure to reduce the water content of chicken manure; If the water content is too low, add fresh chicken manure or sprinkle some water. The chicken manure is piled up on the fermentation platform. At this time, the height is about 1-1.2 meters, the length and width are 1.5-2 meters square, and the volume of compost is generally 1.5 cubic meters.

(3) Fermentation process management

In the fermentation process, the control of temperature is very important. The temperature is too low to reach the maturity standard; When the temperature is too high, the nutrients of compost are easy to lose. The temperature inside the compost is 30 cm from the outside to the inside. Therefore, the metal rod of the thermometer used to measure the temperature should be longer than 30 cm. When measuring, it should be inserted into the compost for more than 30 cm to correctly reflect the fermentation temperature of compost. After composting, chicken manure entered the first fermentation stage. It will automatically heat up to 55 ℃ for 5 to 7 days, then it can kill most of the parasite eggs and harmful bacteria, reaching the harmless treatment standard. After 3 days or so, turn the pile once, which is conducive to ventilation, heat dissipation and even decay. After 7-10 days of fermentation, the temperature in the compost will drop to below 40 ℃. At this time, the color of bio organic fertilizer will turn to dark brown or yellowish brown. There are a lot of white hyphae on the surface of the organic fertilizer inside the compost. There is no raw chicken manure, no maggots, no odor, and a slight ammonia smell. This meets the maturity standard and can be directly used as base fertilizer or topdressing in the field.