views

Pellet production of disc organic fertilizer granulation process

The disc organic fertilizer granulation process can feed the material to the next process uniformly and continuously, and can bear a large bin pressure. As a fine material feeding equipment, it is suitable for conveying various non cohesive materials in powder, material or small state, such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay and other powder, granular or small block materials.

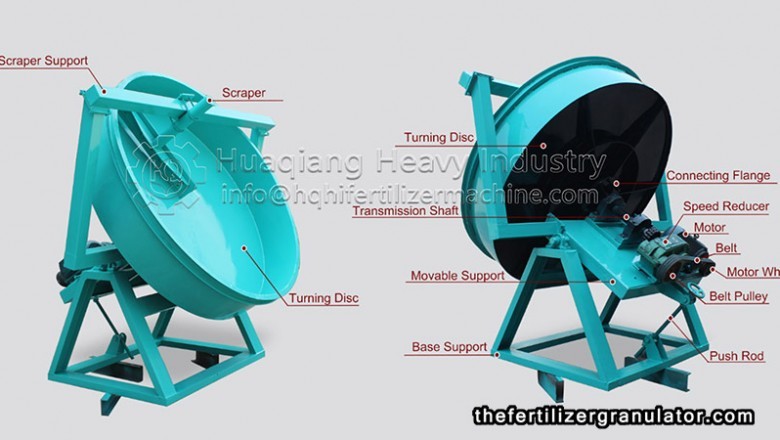

The disc angle of the disc granulator adopts the whole arc structure, and the granulation rate can reach more than 93%. The granulator machine for fertilizer is equipped with three discharge ports, which is convenient for intermittent production operation, greatly reduces the labor intensity and improves the labor efficiency. The reducer and motor are driven by flexible belt, which can start stably, slow down the impact force and prolong the service life of the equipment. The bottom of the pelletizing plate is reinforced by a plurality of radiating steel plates, which is firm and durable without deformation. Heavy, thickened and solid base design, without anchor bolt fixation, stable operation.

Pellet production of disc organic fertilizer granulation process

1. For example, the disc organic fertilizer granulator can pass through the tilt angle of the disc body, the more flat the disc body, the larger the particle size, and the steeper the disc body, the smaller the particle size.

2. According to the control of material moisture, the larger the moisture content is, the larger the particles are, and the smaller the moisture content is, the smaller the particles are.

3. According to the speed of the fertilizer pellet machine, the higher the speed, the smaller the particles, and the lower the speed, the larger the particles.

In general, the uneven particles of organic fertilizer are mostly due to the uneven mixing of materials and the coarse fibers.