views

Organic fertilizer raw materials are processed by machines

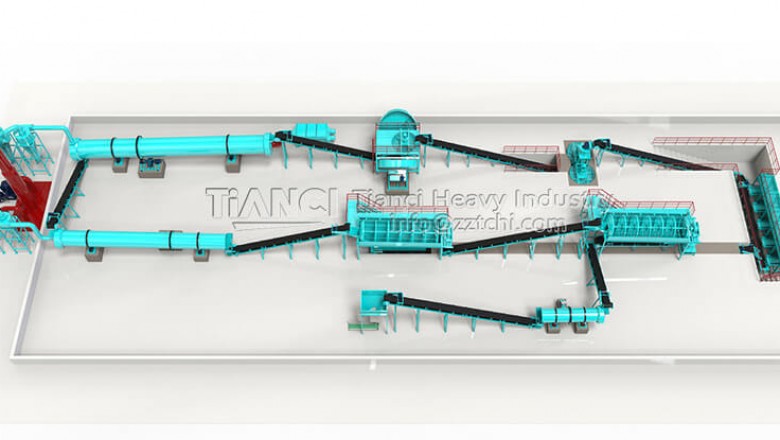

The production process of organic fertilizer production line generally includes: raw material selection → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The process of organic fertilizer production line: ferment the raw materials of organic fertilizer (animal manure, domestic garbage, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) into semi wet materials for crushing, and then add nitrogen, phosphorus, potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) to make the minerals in organic fertilizer meet the standard, Then, the mixer is used to stir and enter the granulator machine for fertilizer of the particles. Then, the particles are dried and sieved by the screening machine. The qualified products are packaged and the unqualified products are returned to the granulator for granulation.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce fertilizer granulator, crusher, mixer, conveyor, compost windrow turner, double roller granulator, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer production line, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!