views

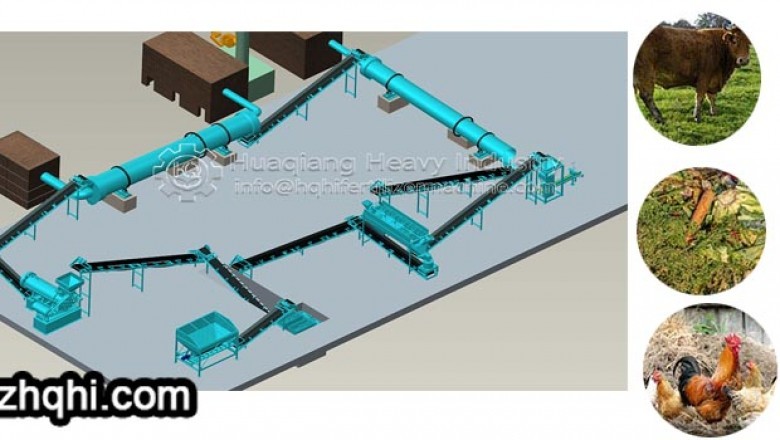

How to produce cow manure organic fertilizer by using cow manure organic fertilizer production equipment?

From the point of view of cattle farm, cow dung is a kind of waste. It has become the focus of people's attention whether we can carry out secondary development and make full use of it. Now, in order to develop the organic fertilizer industry, various kinds of advocacy and encouragement policies have appeared, and the time for the large-scale and industrial development of cow manure commercial organic fertilizer has become mature. How to make manure into organic fertilizer?

The cow manure organic fertilizer production process is mainly divided into two parts: pretreatment part and granulation production part.

The production technology of cow manure organic fertilizer equipment is introduced in detail

Step 1: fermentation

The cow dung and urine are collected and mixed with hay and rotten silage to make compost and ferment. In the process of fermentation, the compost machine is used to make the cow dung fully ferment. Only by turning the pile in time and evenly can this be achieved. Now some places are very dry and some places are very wet, which will affect the quality of fermentation.

The second step: ingredients crushing and mixing

The composted materials, inorganic fertilizers such as N, P, K, and other additives are crushed, proportioned and mixed by material crusher and horizontal mixer according to a certain proportion.

Step 3: Granulation

A new type of organic fertilizer granulator was used to granulate the materials in the organic fertilizer production line.

Step 4: screening and return system

There is a certain difference in the particle size of the granulated material exported from the granulation and molding system, which needs screening and grading. The selected rotary screen requires small vibration, low noise, convenient screen change, and equipped with screen surface cleaning device. It is suggested that an automatic return system should be equipped to screen the large and small particles of unqualified materials, which will be transported out through the belt elevator, crushed again and sent to the granulator to continue granulation, which will help to improve the continuous operation capacity of the production line.

Step 5: drying

The organic fertilizer dryer is used to further remove the moisture of the screened particles to meet the standard requirements of the moisture content of organic fertilizer.

Step 6: cooling

Cooling the granular materials with a cooler is helpful for the storage and quality assurance of particles.

Step 7: packaging

The cooled granular materials are transported to the finished product warehouse by bucket elevator. The granular materials are weighed and packed quantitatively by automatic packing scale.

There are two steps to process commercial organic fertilizer in the organic fertilizer production line: early fermentation and treatment part and deep processing granulation part. Organic fertilizer equipment needs fermentation compost windrow turner, crusher, mixer, fertilizer granulator, dryer, cooler, screening machine, coating machine, packaging machine, conveyor and other equipment. Organic fertilizer production plant cost about 250000 yuan.