views

How to make sewage sludge into organic fertilizer?

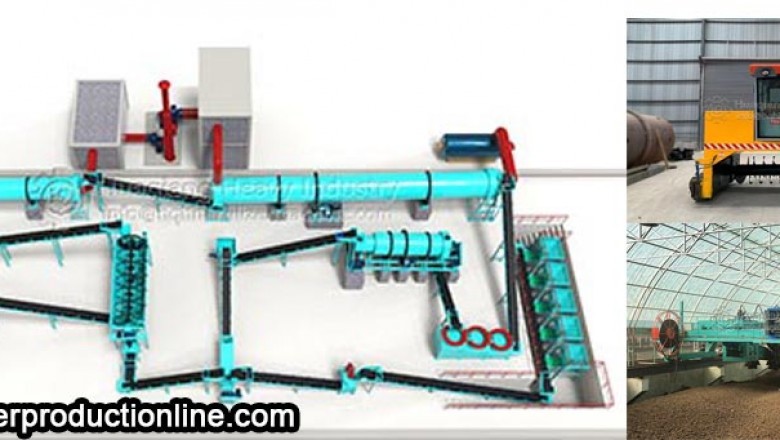

Let's look at the sludge organic manure production process

1. Adjust raw material moisture:

The sludge in water treatment plant generally has high water content, about 75% - 80%. Generally, it has been anaerobic fermentation, and the content of harmful bacteria is not high. When it is transported back to the fermentation plant, the raw materials with low water content should be laid under the fermentation tank, and then the water absorbing auxiliary materials should be laid on the top to make full use of the liquid organic fertilizer, which can increase the nutrients in the raw materials and make the materials in the fermentation process sufficient The moisture content is 50% - 55%.

Adding water absorbing auxiliary materials to sludge, such as domestic waste and crushed crop straw, branches, leaves and sludge fertilizer with low moisture content after backfilling and fermentation: general sludge accounts for 60% - 70%, and domestic garbage and other water absorption auxiliary materials account for about 30% - 40%.

2. Adding sludge starter (RW rot promoter)

Adding sludge starter to the sludge is usually added before fermentation. The fermentation bacteria are evenly mixed with the sludge through the action of tossing and stirring by the compost machine. The addition amount of compound fermentation bacteria agent is generally about 0.1% - 0.3%. As long as the sludge starter is applied into the sludge.

3. Composting:

High temperature fermentation can effectively kill pathogenic microorganisms and Ascaris eggs in sludge, fix heavy metals in microorganisms, or turn them into insoluble carbonate, so as to prevent heavy metals from entering the food chain. When the temperature reaches 65-70 ℃, it can be turned over and cooled. When the fermentation temperature is too high, the beneficial bacteria in the raw materials will be killed. When the content of beneficial bacteria in the finished product is not up to the standard, it can be out of the tank after 5-7 days of fermentation in summer and 12-15 days in winter. The storage plant is placed for stacking fermentation for 3-5 days, and granulation can be carried out when the water content is 35% - 40%.

Generally, there are two kinds of fermentation methods: the ground strip fermentation by using the ground compost fertilizer production machine; and the tank type tumbling fermentation by using the tank tipper. The sludge organic fertilizer production process introduced in this paper is the tank type fermentation overturning machine.

4. Material crushing:

As the fermented materials contain small caking, which is not conducive to the granulation of the finished product, the material can be crushed and can be carried out by organic fertilizer crusher with the number of 1-2 sets and the power of 30KW × 2.

5. Material mixing:

The crushed materials are transported to the batching bin, and then sent to the main conveyor through automatic batching, and then sent to the mixer for mixing.

6. Material granulation:

Small and medium-sized production of organic fertilizer generally use disc granulator for granulation, which can save investment cost and high pelletizing rate, which can reach more than 93%. There are three kinds of particles: large, medium and small. The angle of the granulation plate must be adjusted to a certain position. The angle is determined according to the particle size. The larger the angle is, the smaller the particles are. The smaller the angle is, the larger the particles are.

Huaqiang heavy industry recommends users to use the "new type of organic fertilizer granulator". This equipment not only has a higher pelletizing rate than the disc granulator, but also can produce organic fertilizer with organic content as high as 100%, and the product value is higher.

7. Drying and cooling process of organic fertilizer:

The granulated semi-finished organic fertilizer particles are sent to the dryer through the main conveyor for drying. The drying temperature is controlled below 70 degrees. Because the moisture content of the feed is about 35% - 40%, the beneficial bacteria in the raw materials will be killed if the temperature is too high. The retention time of the granules in the dryer is 40-45 minutes, and the rotation speed of the dryer is 4.5-5 revolutions, which can reach the outlet.

The dried finished organic fertilizer particles are sent to the primary screening machine through the conveyor to separate the large, medium and small particles. The large particles are sent to the crusher for crushing and granulation through the return belt in fertilizer production line. The medium and finished materials are sent to the cooler for cooling by the conveyor. Because the particles have a certain temperature, the particles are sent after cooling, and the fine particles are separated by two screening.

8. Finished product packaging

The screened organic fertilizer product particles are sent to the organic fertilizer automatic packaging machine through the conveyor, and the finished biological organic fertilizer can be produced by metering and packaging.