views

How to know about the electromagnetic stirrer?

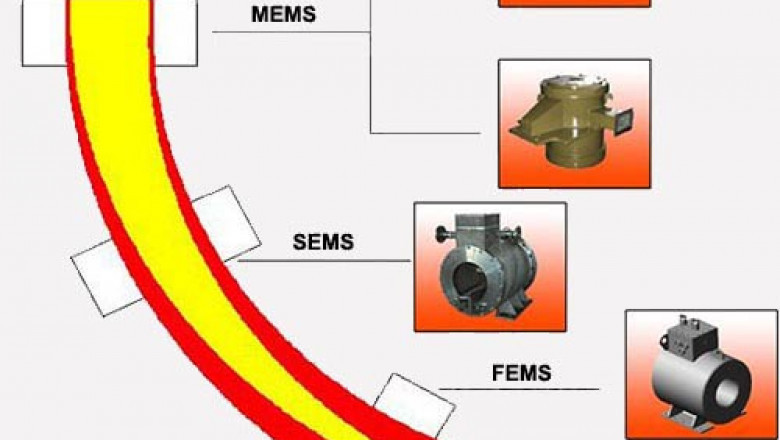

In contrast to conventional mechanical and decompression stirrers, the electromagnetic stirrer employs the linear motor principle and is a noncontact stirrer in which no part touches the molten steel. The continuous direct process uses an electromagnetic stirrer to boost harden production and enhance product quality. Stirrers can be classified as mold, strand, or final stirrers based on their position along the casting strand and metallurgical effects. Surface and subsurface quality, as well as internal and central soundness in the form of separation, porosity, and central break, is among the advantages that can be achieved by combining one or more EMS.

How to work?

Chemists and biologists who work in the lab frequently use magnetic stirrers. They are well-liked by researchers worldwide due to their portability, low cost, and ease of use. They can be used for many different things, but here are three everyday experiments you can do with them.

Uses of crane wheel

When we appear at the large overhead crane operation and functioning above, most of us overlook the burden of the weight and press the little crane wheel at the base of each apparatus of the crane. The excellence of the crane sweep will make an important effect on the crane. The crane wheel is utilized to load the heaviness and ability of the crane stiff and trolley while moving and drifting.

We can offer crane wheels from a particular crane circle to the whole place of crane wheel sets. By following the excellent values and knowledge in industrializing these products, our crane veer can assure strength, adequate casting and well-organized consequences. Our clients can avail the entire product range at an important market price. Wheel blanks are utilized in heavy-duty use like wind motors, engine grip drives, mining equipment, and speed depressors.