views

Composition of organic fertilizer production line and equipment

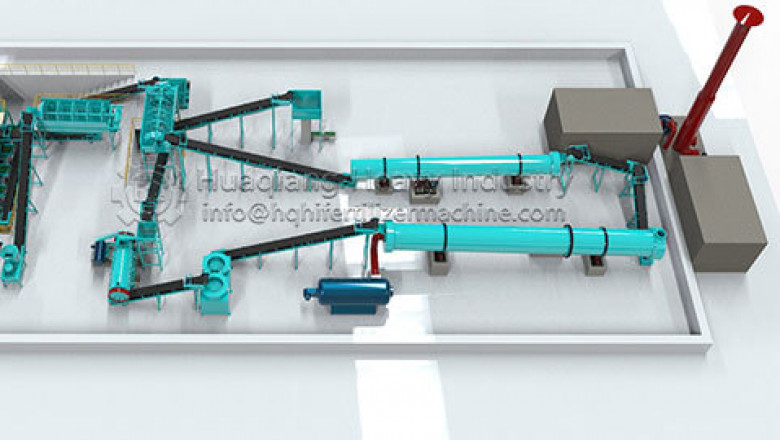

After the fermentation, the raw materials of the organic fertilizer production line will be crushed into powder in the organic fertilizer crusher. The powder will be added into the organic fertilizer mixer for mixing. After mixing evenly, it will be put into the granulator to make granules. The prepared granules will be put into the dryer to reduce the moisture content of the granules to 10-20%. After cooling, it will be put into the cooler for cooling. After cooling, it will be put into the screening machine for screening, The unqualified products screened out can be recycled to the pulverizer by the return belt conveyor, and the screened products can be directly packaged.

Composition of organic fertilizer production line and equipment

1. Fermentation compost windrow turner: it can ferment and turn the materials in the fermentation process.

2. Crusher: crushing high humidity materials and other raw materials in the organic fertilizer production process.

3. Mixer: to mix a variety of raw materials.

4. Granulator: Granulation of mixed materials; easy to separate and package.

5. Dryer: drying granular materials with certain humidity.

6. Cooler: it can quickly cool the dried materials and increase the production efficiency.

7. Screening machine: screen and grade the finished fertilizer.

8. Coating machine: the particles are coated outside to prevent the caking of fertilizer.

9. Automatic weighing and packaging machine: quantitative bagging and packaging of finished products.