views

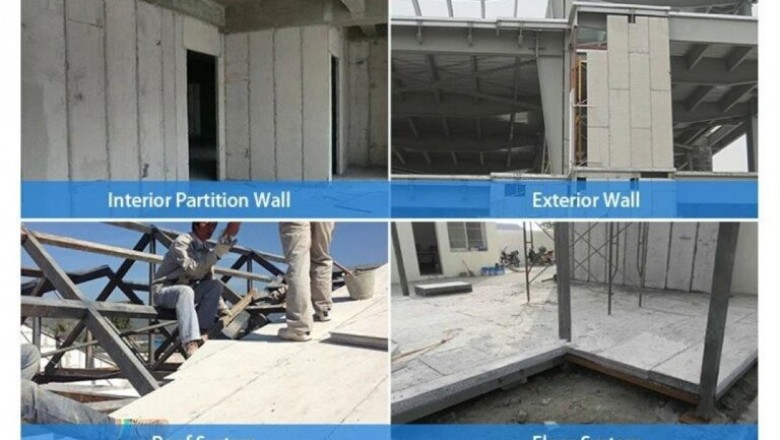

Sandwich wall systems are specialized cladding systems consisting of 3 layers; one thick core layer of low typical strength and density and two outer metal plates. The thick centre is definitely an insulating core and is normally produced out of mineral wool. The two outer plates are produced of steel, which delivers the top protection. The three layers are connected to each and every other by way of specialized adhesives. Get more information regarding EPSCement Sandwich Wall Panel

Sandwich panels are generally used for external and internal architectural cladding and/or partitioning. These panels can be applied within the onshore and offshore oil & gas industry, wind energy industry and the infra & defense industry.

But what are the exact benefits of a sandwich wall system on a structure? We have outlined them below:

1. Weight saving

Due to its lightweight characteristic a sandwich panel saves a lot of weight on the applied structure. The inner core of insulation and the thin plates have an approximate weight of 21 kg/m2 at 100 mm panel thickness.

2. Fast installation

Because of its lightweight, the panels could be transported and installed very effectively and efficiently. Consequently, it saves you a lot of time and labor costs.

3. Good thermal insulation

The mineral wool insulation offers good thermal protection. Thermal insulation is important because it allows for temperature regulation inside the compartments. Temperature is kept at a comfortable level in order to provide a pleasant working environment for personnel.

4. Excellent non-combustible and acoustic performance

The insulation is required to be non-combustible to ensure fire safety. Non-combustible materials withstand the spread of fire and therefore are processed into the insulation material.