views

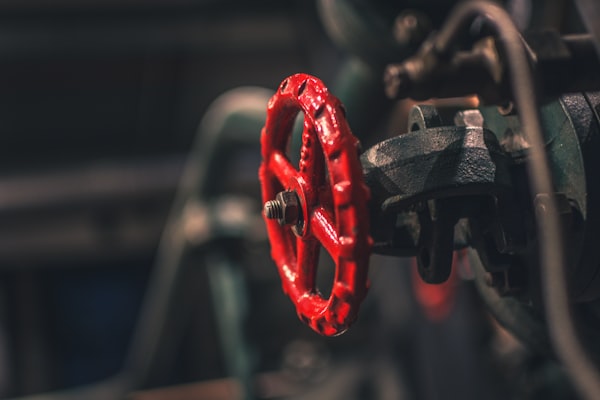

Most people take the comfort they enjoy for granted, but this is the result of numerous projects that have been put in action with great effort. The engineers who are charged with turning simple ideas into working mechanisms have a number of challenges to overcome to see the results of their actions. To achieve the goals they set out for, they have to find the help they need to get the job done properly. As it is with any custom project, they need customized elements to serve the purpose they are intended for such as a gate valve, a butterfly valve or any other thing like that.

The Features of a Gate Valve and what It Is Used for

There are many different systems today that are a result of engineering marvels that have been designed decades ago. They may be simple solutions that can solve serious problems, but they are still useful today, yet they have to be adapted to the projects they are a part of. For instance, a gate valve is a valve that can be opened or closed by lifting or lowering a barrier out of or in the path of a fluid. It may be an old design, but it still has a wide range of applications to this day.

The faces of the gate that opens or closes can be parallel, but usually they have a wedged design so the gate valve can withstand higher pressures and seal the surface. When they are fully open, they hardly restrict the flow of the liquid. Due to the simple construction of the valve, they do not occupy too much space along the course of the pipes and this makes them easier to install. This is why they are one of the preferred solutions for installations of petroleum, water, gas and more.

A gate valve can have a number of designs, depending on the application for which it is used. A bonnet can provide the means to create a seal that will prevent any leaks from liquids. A pressure seal bonnet can create valves that can withstand high pressures and they can be used for steam or gas installations. A knife design has an edge similar to a knife which makes it ideal for materials with higher viscosity such as slurries or paper pulps. Each choice depends on each application.

How a Butterfly Valve Works in Various Situations

There have been many new designs created over time and each of them has been improved and adapted to suit the demands of a system. Simple designs have been enhanced so they can work in various applications and with different substances to control their flow properly with the least amount of effort. A butterfly valve is part of the family of quarter-turn valves. This is a group of mechanisms that needs a quarter of a turn to fully open the valve for the liquid to pass through.

A disc is positioned in the middle of a pipe with a rod that passes through its center. This rod is connected to each side of the pipe and on one end is has a lever or a handle that will allow users to open and close the butterfly valve. One of the aspects that must be considered is that the disc is always present in flow of the liquid and this will cause a small drop in the pressure, even if it is fully open. This does not cause any disruptions, but it is still something to be considered.

As it was pointed out before, the design has changed over time and it was improved in many ways to withstand the pressures as well as the materials that must be transported through the pipe projects they were used in. Each option has its own benefits and it is important to know which the best solution is for a certain application. On top of that, it is important to find a supplier that can rise up to the demands of the project and has the capacity to deliver the orders on time as well.

The Answers that will Rise Up to the Demands of Each Project

There are still a number of valve designs that must be considered and each of them is suitable for a number of applications, but it is important to find out how it is made. The materials that are used in the manufacturing process range from cast iron, cast steel and forged steel up to stainless steel for certain industries. People who want to use them, must know what they need to get the job done properly and they have to find a supplier that can rise up to the demands from the start.

There are quite a few options on the market today and each of them can make promises, yet not all of them can meet them. This is why it is important to take the time to learn more about the suppliers that are able to deliver a tailored solution that will work on the project, they should find the ones that work with different materials to suit the needs of their clients and so on. The web is one of the first places that can provide answers about the capacity of the suppliers, the quality of the products they deliver as well as the deadlines they are able to meet with every order.

The more time people invest in this, the surer they can be about the choices they make when it comes to the supplier, the quality of the gate valve they want to order as well as the deadline they are going to meet. The reviews of other users will point in the right direction and they will also provide many of the answers needed. This is a decision that can make or break the entire system and this is why people must be aware of the choice they are about to make and the butterfly valve that will be installed to control the flow of the liquid.