views

Butyl Rubber Market size is forecast to reach $5.2 billion by 2025 after growing at a CAGR of 5% during 2020-2025. Butyl rubber is an isobutylene copolymer with a small amount of isoprene. The special properties such as permeability to gas, excellent resistance to heat, chemicals & ozone and high low-temperature flexibility are making it prominent material into rubber, tubes and tires application. Tires made of butyl rubber have excellent inflation pressure retention, which makes them a preferred tire solution for various types of vehicles including passenger and commercial vehicles.

Report Coverage

The report: “Butyl Rubber Market- Forecast (2020-2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the Butyl Rubber industry.

By Type: Brominated Butyl Rubber, Regular Butyl Rubber, and Chlorinated Butyl Rubber.

By Application: Coatings, Adhesives and Sealants, Tubes and Tires, Wires and Cables, Gaskets, Membranes, Footwear, Conveyer Belts, Protective Clothing and Others.

By End Use: Automotive, Healthcare and Medical, Pharmaceutical, Construction, Industrial, Textile industry, Rubber Industry and Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Download Report Sample @ https://www.industryarc.com/pdfdownload.php?id=1267

Key Takeaways

- Asia-pacific dominates the Butyl Rubber market owing to the rising industrialization and automotive sector.

- China and India exhibit the highest butyl rubber consumption in Asia Pacific. Some of the region's other important butyl rubber consumers include Malaysia, Vietnam, Hong Kong, Macau, Indonesia, Australia and the Republic of Korea.

- The high volatility in natural rubber (NR) prices has been a major driver for the growth of the industry.

By Type– Segment Analysis

Regular Butyl Rubber segment held the largest share in the Butyl Rubber market in 2019. The increasing use of regular and chlorinated butyl in tire manufacturing is expected to provide a positive space for the growth of the market over the forecast period. The use of these products offer benefits such as consistent inflation pressure, durability, and heat stability. The increasing use of regular and chlorinated butyl in tire manufacturing is expected to provide a positive space for the growth of the market over the forecast period. The use of these items provide benefits such as constant temperature pressure, longevity, and heat control. Higher curing rate coupled with product vulcanization efficiency is anticipated to drive demand for the product. The product's advantages in terms of adhesion, as opposed to generic butyl, are expected to fuel market growth over the forecast period.

By Application– Segment Analysis

Tubes and Tires segment held the largest share in the Butyl Rubber market in 2019. Rubber is a major fabricating component of a tire. In the manufacturing process there are three categories of rubber used: natural rubber (NR), styrene butadiene rubber (SBR), and polybutadiene rubber (PBR). Among various application areas for butyl rubber, tires and tubes are constantly in their position as the dominant segment in the global market. Over 200 raw materials make up the composition of a tire, ranging from: wire, rubber, chemicals, black carbon, oil, nylon, polyester, and steel. Passenger car tires make up the bulk of the production of tires, with 45% of all tires produced, followed by 30% truck and bus tires. The smallest group of tires produced are Industrial tires. Passenger tires are designed for a diverse range of driving experiences. The U.S. In 2018 Tire Manufacturers Association (USTMA) reported that $46.2 million tires were shipped for OEM and 214.9 million were shipped as replacement tires.

By End Use – Segment Analysis

Automotive segment held the largest share in the Butyl Rubber market in 2019 growing at a CAGR of 7%. As the economies are developing, people are spending more on automobiles. With the growth in vehicle production, demand for tires in the OEM market is expected to rise. This will have a positive effect on the tire industry as more than 60 per cent of the global natural & synthetic rubber produced is consumed during tire & tube manufacturing. Butyl rubber is an indispensable raw material used in tire and tube manufacturing, and an increase in global demand for tires and tubes is expected to increase butyl rubber demand during the forecast period. The most critical divisions of the automotive industry include commercial vehicles and passenger cars. China ranks among the world's largest automobile markets, in terms of both sales and production. Car sales in China first plunged in 2018; the market has not since recovered.

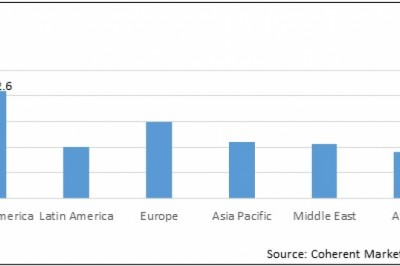

Geography - Segment Analysis

Asia-Pacific (APAC) dominated the Butyl Rubber market consisting share of 40% followed by North America and Europe. The growth in the region is supported by the automotive sector. The APAC has the greatest growth potential, with rising passenger mobility as well as a growing middle class and increased access to medical care, thus underscoring the urbanization trend, says the firm. Adding to this is the global trend of radial, tubeless truck and bus tires, all factors that will bode well for the rubber material market. India's tire makers are gearing up to intensify their position in the modernization process, largely driven by demand and supply conditions as well as being to some degree directly proportional to car sales. It is expected that tire exports will rise by 8-10% over the next three years, powered by stable demand and increased acceptance of Indian tires, both in terms of quality and price. With Chinese low-cost tires increasingly penetrating overseas markets , particularly after the US removal of the anti-dumping duty (ADD) on Chinese tires in 2017, competition from China (both in terms of volumes and pricing) will remain a key challenge.

Amid COVID-19, the outlook for 2020 global automotive sales becomes more difficult. Currently the butyl rubber industry has been affected due to COVID-19 pandemic where most of the industrial activity has been temporarily shut down. In in turn has affected the demand and supply chain as well which has been restricting the growth in year 2020.

Inquiry Before Buying @ https://www.industryarc.com/reports/request-quote?id=1267

Drivers –Butyl Rubber market

Outstanding Properties of Butyl Rubber will drive the market

Butyl rubber has excellent properties such as excellent chemical resistance, highly flexible temperatures used in tires and tubes. It has the property of gas permeability and it will increase the tire's life. Its low gas permeability and flexibility make it the ideal material for tire inner tubes. Butyl rubber is driving the market with the introduction in Automobile industry. Other than tires it is also used in sealants, adhesives, protective suits tubes electrical cable and others.

Challenges – Butyl Rubber market

Fluctuation in the price of raw material can restrict the market growth

Butyl rubber market faces a challenge with the price fluctuations of raw materials and government policies that effect Butyl rubber's price. Anti-dumping duty levy on carbon black rubber products has elevated the rubber quality. Butyl rubber during manufacturing is difficult to handle, due to its tendency to trap air and creep. Another obstacle for the industry is environmental issues, because exposure to chemicals in rubber production remains a major health issue. It has low resistance to aromatic hydrocarbons, aliphatic carbohydrate.

Schedule a Call @ https://connect.industryarc.com/lite/schedule-a-call-with-our-sales-expert

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Butyl Rubber market. In 2019 the Butyl Rubber market has been consolidated by the top five players accounting for xx% of the share. Major players in the Butyl Rubber market rare Exxonmobil Chemical, Lanxess AG, Japan Butyl Company, Kiran Rubber Industries Pvt. Ltd., Reliance Industries Ltd, and Others.

Acquisitions/Technology Launches/ Product Launches

In September 2019, Sibur and Reliance Industries Ltd. have launched butyl rubber production at the joint integrated petrochemical plant Reliance Sibur Elastomers Private Ltd. in the Indian city of Jamnagar. The production facility will have annual capacity is 120,000 tonnes.

In November 2019, Sibur has closed the sale of some of its synthetic rubber production assets in Togliatti to Tatneft. Tatnef has acquired Sibur's production facilities for various types of synthetic rubber, MTBE high-octane fuel component, butadiene, isoprene, and other intermediates. The facility has the capacity to produces 82,000 metric tons per year of emulsion styrene butadiene (ESBR 60) and butyl rubber (IIR75).

For more information about chemicals and materials ,Please click here