250

views

views

Prepregs are composite materials in which a reinforcement fiber is pre-impregnated with a thermoplastic or thermoset resin. Prepregs have unique properties as they are cured under high temperatures and pressures. Most common reinforcements used for prepreg are glass, carbon and aramid fibers.

Prepregs are composite materials in which a reinforcement fiber is pre-impregnated with a thermoplastic or thermoset resin. Prepregs have unique properties as they are cured under high temperatures and pressures. Most common reinforcements used for prepreg are glass, carbon and aramid fibers. Prepregs are produced using two main processes namely hot melt process and solvent dip process, with a range of materials, including woven fabrics, UD prepregs and multiaxial range of fiber types. Prepregs are used in high performance applications in the composites industry and also in other sectors.

The major drivers of growth for this market are in applications such as aerospace, defense, wind energy, and automotive and escalated demand for lightweight, environment-friendly, and efficient products. Advantages of corrosion resistance, higher strength-to-weight ratio, lower maintenance, and a longer lifecycle than other traditional materials, like aluminum and steel are additional factors contributing to the market growth. Growth of key end-use industries, such as aerospace and wind energy is expected to remain a key driving factor for the global prepreg market.

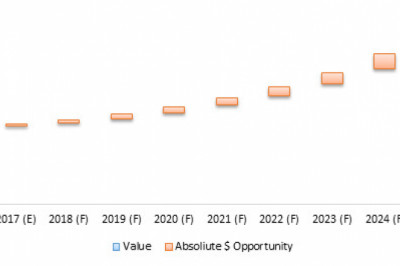

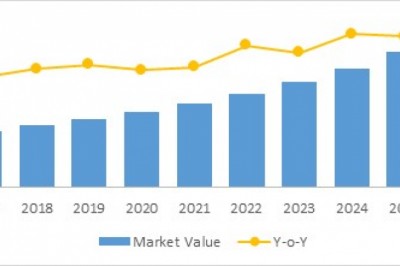

The global prepreg market is forecast to grow at a CAGR of XX% from 2016 to 2021 and is expected to generate revenue of $XX Billion by 2021. The aerospace segment is expected to record the highest growth during the forecast period. The aerospace market is predicted to remain robust due to strong back orders for Boeing 787 and Airbus 380 aircraft. New products, including COMAC 919, are expected to increase the production rate of aircraft from eight per year to 200 per year by 2021.

The common resins for Thermoplastic prepregs include PP, PET, PE, PPS, and PEEK. The primary difference between thermoset and thermoplastic prepreg is that thermoplastic prepregs are stable at room temperature, and generally, do not have a shelf life. The primary resin matrix used is epoxy. However, other thermoset resins are made into prepregs including BMI and phenolic resins.

The advantage of using prepregs is their ease of use. They come with a backing film on both sides of the fabric to protect it during transit and preparations. The prepreg is cut to the desired shape, the backing is peeled off, and the prepreg is then laid into the mold or tool.

Fiber orientation or fiber architecture is important in providing the correct amount of strength and stiffness in the specified areas. Many different fabrics and cloths can be prepreged. Woven fabrics, stitched fabrics, and hybrids can be turned into a prepregs. Prepreg tapes can be used to wrap a mandrel. Strips and sections can be cut and placed exactly where strength is required.

North America is currently the largest market for Prepreg. APAC is anticipated to witness the highest growth with a CAGR of XX% during the forecast period of 2016 to 2021 and this will continue over the next seven years in light of the liberal policies presented by the government to lure the global manufacturers for setting up of facilities in these regions. Middle East and Africa currently hold a smaller share but is foreseen to witness considerable growth in terms of economical land and labor rates in the region. Emerging economies such as Brazil and Mexico are expected to have high potential for prepregs due to rapid industrialization of these economies.

The major drivers of growth for this market are in applications such as aerospace, defense, wind energy, and automotive and escalated demand for lightweight, environment-friendly, and efficient products. Advantages of corrosion resistance, higher strength-to-weight ratio, lower maintenance, and a longer lifecycle than other traditional materials, like aluminum and steel are additional factors contributing to the market growth. Growth of key end-use industries, such as aerospace and wind energy is expected to remain a key driving factor for the global prepreg market.

The global prepreg market is forecast to grow at a CAGR of XX% from 2016 to 2021 and is expected to generate revenue of $XX Billion by 2021. The aerospace segment is expected to record the highest growth during the forecast period. The aerospace market is predicted to remain robust due to strong back orders for Boeing 787 and Airbus 380 aircraft. New products, including COMAC 919, are expected to increase the production rate of aircraft from eight per year to 200 per year by 2021.

The common resins for Thermoplastic prepregs include PP, PET, PE, PPS, and PEEK. The primary difference between thermoset and thermoplastic prepreg is that thermoplastic prepregs are stable at room temperature, and generally, do not have a shelf life. The primary resin matrix used is epoxy. However, other thermoset resins are made into prepregs including BMI and phenolic resins.

The advantage of using prepregs is their ease of use. They come with a backing film on both sides of the fabric to protect it during transit and preparations. The prepreg is cut to the desired shape, the backing is peeled off, and the prepreg is then laid into the mold or tool.

Fiber orientation or fiber architecture is important in providing the correct amount of strength and stiffness in the specified areas. Many different fabrics and cloths can be prepreged. Woven fabrics, stitched fabrics, and hybrids can be turned into a prepregs. Prepreg tapes can be used to wrap a mandrel. Strips and sections can be cut and placed exactly where strength is required.

North America is currently the largest market for Prepreg. APAC is anticipated to witness the highest growth with a CAGR of XX% during the forecast period of 2016 to 2021 and this will continue over the next seven years in light of the liberal policies presented by the government to lure the global manufacturers for setting up of facilities in these regions. Middle East and Africa currently hold a smaller share but is foreseen to witness considerable growth in terms of economical land and labor rates in the region. Emerging economies such as Brazil and Mexico are expected to have high potential for prepregs due to rapid industrialization of these economies.