views

Regional Analysis

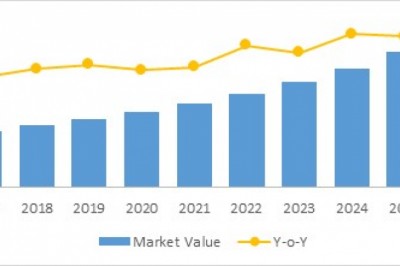

North America contributes the largest share in the global high-performance market due to the US government directive to enhance fuel efficiency for new automotive to about 54.6 miles per gallon by the end of 2027 which has increased the usage of high-performance composites. Asia-Pacific is significantly growing with healthy CAGR owing to robust demand for fuel efficient and lightweight composite materials in the automotive and aerospace industries.

The regional market in Europe is projected to grow with healthy CAGR owing to the presence of large number of automotive parts manufacturers in the region. Advancement in technology in the field of vehicles aesthetical design and speed is increasing the demand for high-performance composites in automotive industries.

Market Overview

High-performance composites materials are a combination of at least two different constituents. Due to its unique combination high performance composites have superior properties such as greater stiffness, strength and thermal conductivity. It comprises of a thermoplastic resin and matrix reinforced by fibers. Compared to conventional materials such as metal and alloys, high performance composites have lighter, stronger, and stiffer attributes. Furthermore, these composites can be customized to exhibit high electrical or thermal conductivity, sensor capabilities, and stealth characteristic.

The demand for high performance composites is increasing owing to the rising investments for innovating high strength lightweight materials by aerospace manufacturers. Reduction of weight saves fuel, thereby, decreasing the cost and thus results in fuel efficiency. The ability to withstand the extreme weather conditions of high-performance composite is unattainable by conventional materials which makes it an ideal choice of material for applications in construction, aerospace, and automotive industries. Polymer matrix composites are majorly used composites in above mentioned end-use industries owing to low cost and ease of fabrication. Thus, high performance material is replacing conventional alloys and metals due to the increasing demand for lightweight, cost, and energy saving properties that is a key factor driving the global high-performance market.

Competitive Analysis

The leading players in the global high-performance composites market are SABIC (Saudi Arabia), BASF SE (Germany), Owens Corning (US), Solvay (Belgium), TPI Composites (US), TEIJIN LIMITED (Japan), Huntsman International LLC (US), SGL Group (Germany), Hexcel Corporation (US), TORAY INDUSTRIES, INC. (Japan), Albany International Corporation (US), Arkema (France), ARGOSY INTERNATIONAL (US), Northrop Grumman Corporation (US) and 3M (US).

Market Segmentation

The global High-Performance Composites Market has been segregated on the basis of material, application, and region.

By material, the global high-performance composites market is divided into resin and fiber. The resin segment held significant market share in 2020 and is expected to lead during the forecast period owing to low cost and easy availability

On the basis of application, the global high-performance composites market has been divided into automotive, consumer goods, construction, aerospace, electronics, energy, and others. In 2017, the aerospace segment held the largest share of this market. High-performance composites have predominantly been used in aerospace wide body wings, engine blades, single aisle wings, nacelles, rotors, and brackets.