views

KeyHighlights

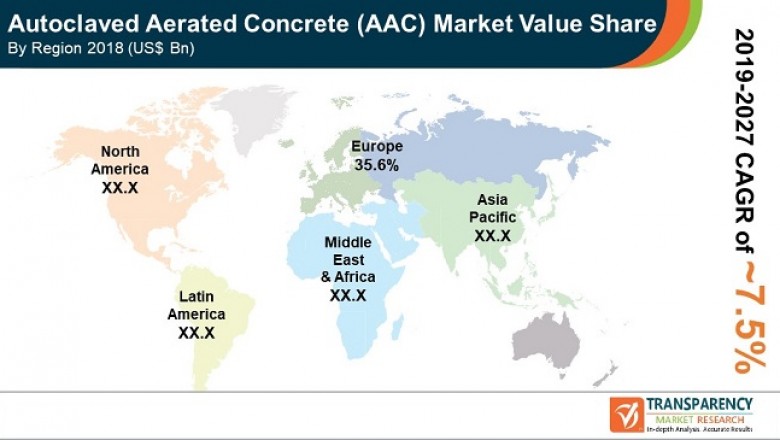

Accordingto a new market report published by Transparency Market Research titled ‘AutoclavedAerated Concrete Market - Global Industry Analysis, Size, Share, Growth,Trends, and Forecast, 2019–2027,’ the global autoclavedaerated concrete market was valued at around US$11.9 Bn in 2018 and isprojected to reach nearly US$ 22.8 Bn by 2027,expanding at a CAGR of above 7% between 2019 and 2027.

Autoclavedaerated concrete (AAC), also known as autoclaved cellular concrete (ACC) orautoclaved lightweight concrete (ALC), is a lightweight precast buildingmaterial whose adoption has been on the rise recently.

Althoughthe product has been used since 1923, it hasgarnered immense popularity recently, due to its ability to provide rigidstructure, insulation, fire resistance, and economy of construction. AAC has aporous structure. It contains pockets of trapped air, which make it lighterthan other building materials. The material can be employed for internal aswell as external construction, due to its high thermal insulation and ease ofinstallation. AAC is used as an eco-friendly green building material inresidential, commercial, and other types of construction. It is manufacturedusing fly ash, which is an unavoidable waste of thermal power plants and isavailable in abundance. Also, AAC is an energy-efficient building material, andit reduces the total cost of construction. Energy consumed for the productionof AAC is less as compared to that for other building materials. AAC consumesapproximately 50% less energy thanconcrete. Tiny air pockets and thermal mass of AAC offer thermal insulation,which reduces construction costs related to heating and air-conditioning. AACreduces heating and cooling requirements by up to 30% dueto its thermal insulation properties, resulting in continued financial benefitsduring the life of the construction.

Increase in Construction SpendingDriven by Expansion of the Construction Sector:

Demand fortraditional building materials is primarily driven by expansion of theconstruction sector globally. Overall increase in construction andinfrastructure-related activities worldwide has resulted in rise in demand forresidential, commercial, and industrial construction, leading to consistentexpansion in the building materials industry. Furthermore, macroeconomicfactors such as GDP growth in Europe, gradual recovery in constructionexpenditure across residential and non-residential sectors, and anticipatedexpansion in the real estate sector supported by government initiatives forproviding affordable housing are expected to drive the autoclaved aeratedconcrete market. Construction of a wall with AAC block walls results in a costsavings as compared to traditional bricks. Due to the low density offered byAAC, the structural load (dead load) is very less, and the structural memberscan be designed accordingly. In turn, the requirement for concrete and steel isless for the foundation and all structural members of the building. The numberof joints is less because of the bigger size of AAC blocks. This reduces therequirement for cement mortar. The labor required to lay AAC blocks is alsoconsiderably less, and this results in considerable time savings.

Request Sample

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=12650

High Investment Costs Associatedwith the Production of AAC:

AAC hasdemonstrated its benefits for more than 70 years, owing to its properties suchas high heat and fire insulation capacity. AAC structural members withreinforcement can be combined in an integrated production with non-reinforcedblock material, etc. The integrated production of reinforced products and blockmaterials requires a qualified plant facility with an advanced reinforcementtechnology. AAC products are manufactured in block factories or in factorieswith an integrated reinforcement technology that allows for the manufacture ofAAC products such as deck and roof elements, wall panels, and lintels apartfrom blocks. In terms of volume, the production of advanced reinforcedcomponents such as panels and lintels has remained subdued as compared to thatof blocks. The investment required for building an integrated productionfacility for manufacturing panels and lintels along with blocks is more thantwice that of a simple block.

A plantdesigned to produce reinforced products is also capable of producing blocks butwith slight modifications. However, plants designed specifically for producingblocks have lower capital cost than those designed to manufacture reinforcedproducts. Moreover, the process time required in case of panels and lintels forpressure rise and curing in autoclaves is almost twice that of blocks.

More Trending Reports

Affordable Housing in EmergingNations:

The demandfor affordable housing is likely to remain robust, driven by a risingpopulation, young demographic profile, shift toward nuclear families, and rapidurbanization. For instance, the market potential of affordable housing projectsin India is expected to touch US$ 930 Bn by 2022.The Indian government’s scheme, Pradhan Mantri Awas Yojana, aims to constructtwo crore (20 million) houses in India, in threephases, till 2022. Housingshortage is expected to increase from the current level of 19million units to 25 million by 2021,based on a stable decadal growth rate.

Request Covid19 analysis on thismarket

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=12650

The demand for Autoclaved AeratedConcrete Market is Primarily Driven by the Increasing Use of AAC Blocks as aPreferred Building Material

Theautoclaved aerated concrete market has been segmented based on product andend-use. Based on product, the autoclaved aerated concrete market has beendivided into block, wall panel, floor panel, roof panel, cladding panel, andothers. In terms of end-use, the autoclaved aerated concrete market has beenclassified into residential, commercial, and others. Blocks was the dominantproduct segment of the AAC market in 2018. In terms ofrevenue, the blocks segment accounted for more than 48% shareof the global autoclaved aerated concrete market in 2018. Thepanel segment is also likely to expand at a significant pace during theforecast period, as panels offer a combination of strength and thermal andacoustic insulation. AAC wall panels are an ideal building solution forlarge-scale, industrial, and commercial construction

Residential Sector on Account ofRapid Urbanization Particularly in Emerging Economies is the Dominant End UserSegment

In terms ofend-use, the residential construction segment dominated the global autoclavedaerated concrete market in 2018. Rise inurbanization, increased purchasing power, growing population, and need foraffordable housing are estimated to drive the autoclaved aerated concretemarket in developing countries during the forecast period. However, lack ofawareness about AAC among construction professionals, builders, developers, andarchitects is likely to act as a restraint for the global AAC market.

Europeis the Largest Consumer and Producer of AAC

Demand forAAC is high in Europe, followed by Asia Pacific and Middle East & Africa.AAC products have been in use in Europe for more than 70 years. Europedominated the global autoclaved aerated concrete market in terms of revenue,accounting for more than 34% shareof the global market in 2018. This isdue to the presence of local AAC manufacturing facilities across Europe, withcountries such as Poland, Russia, Germany, and the U.K. dominating the marketin the region. The autoclaved aerated concrete market in Asia Pacific isestimated to expand significantly during the forecast period. This isattributed to a growing population and rapid urbanization, especially inemerging countries such as China and India. Increase in the number ofinfrastructure and commercial development activities is expected to fuel demandfor AAC in Middle East & Africa. The AAC market in North America isexpected to expand at a steady pace during the forecast period, due toprevalence of wood-based construction across the region and a limited number ofAAC manufacturing facilities. Moreover, government initiatives to promote greenbuilding construction and establishment of state councils in various regions bythe World Green Building Council (WGBC) are likely to propel the AAC market inNorth America and Latin America

Buy Now

https://www.transparencymarketresearch.com/checkout.php?rep_id=12650<ype=S

Enhancement of ProductionCapabilities by Key Players

Key playersprofiled in the report of the autoclaved aerated concrete market include XellaGroup, H+H International, SOLBET, ACICO, AERCON AAC, UltraTech Cement Ltd.,Biltech Building Elements Limited, AKG Gazbeton, Bulidmate, Eastland BuildingMaterials Co., Ltd., Brickwell, and UAL Industries Ltd. Majorplayers operating in the market are investing significantly in the expansion ofproduction capacity in order to meet the increase in demand. For instance, CSRHebel, Australia’s leading manufacturer of high-quality autoclaved aeratedconcrete (AAC), expanded its production capacity by building a secondproduction line in Somersby, Australia in September 2017. Thishighly automated plant is specially designed for panel production only and isexpected to have a capacity of 300,000 cubicmeters per year. The facility is equipped with the latest available Aircretetechnology, making it one of the world’s most advanced and highly automated AACpanel plants.