views

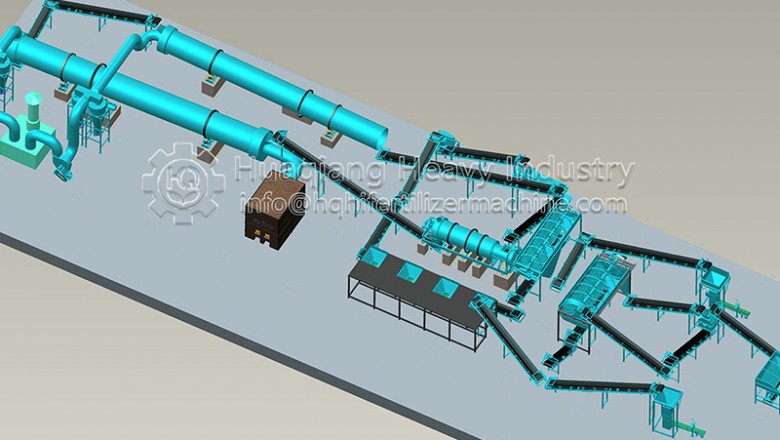

How to granulation production process of livestock manure organic fertilizer equipment

In order to meet the environmental protection standards, the key lies in the treatment of livestock manure.

Trough type compost fertilizer production machine: transport the materials to the fermentation trough, stack the materials for 3-4 days, the temperature reaches 55 ℃, and then use the trough type compost turner to overturn, so as to achieve the effect of uniform materials.

High humidity material crusher: crush the fermented material to meet the next processing standard.

Double shaft mixer: transport the crushed materials to the mixer fertilizer production machine for mixing (adding necessary additives during the mixing period), so that the materials are evenly mixed.

Disc granulator: Transport evenly stirred materials to granulator for granulation.

Drum dryer: because the material moisture is too high to use, it needs to use the drying equipment to dry and evaporate the moisture in the material.

Roller Cooler: after a series of program processing, the temperature of the material can reach more than 100 degrees, the temperature is very high, so it needs to be cooled down.

Drum screening machine: the main function of the screening fertilizer production machine is to screen out the material particles that are too small or too large for secondary crushing. The qualified material particles can be packaged and sold.