views

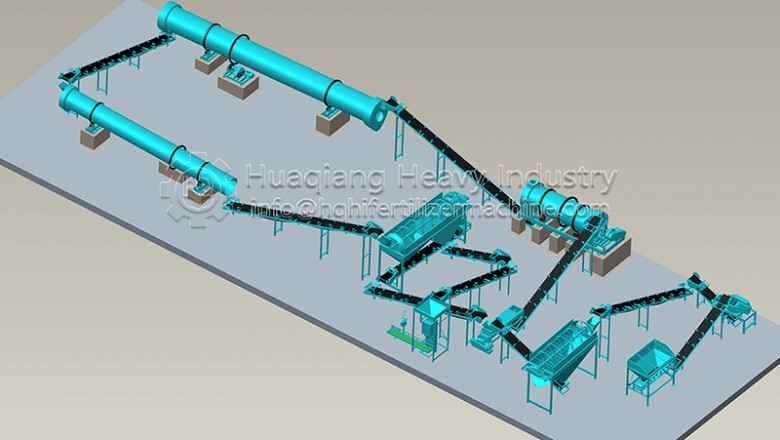

Farm equipped with organic fertilizer production line

Without the ability to deal with manure independently, the farm was forced to demolish. Traditionally, livestock manure contains a large number of nutrients such as nitrogen, phosphorus, potassium and a large amount of organic matter necessary for crops. If it is possible to use the organic fertilizer production line equipment, it is better to effectively kill the pathogenic bacteria and parasitic eggs in the manure, so as to process the livestock manure that pollutes the environment into organic manure that is beneficial to the soil fertilizer. The livestock manure organic fertilizer production line of Zhengzhou Huaqiang heavy industry research institute can change livestock manure into organic fertilizer and realize the resource utilization of organic waste. It is the best choice for environmental protection production in aquaculture industry.

There are two steps to process commercial organic fertilizer in the production of organic fertilizer: early fermentation and treatment part and deep processing granulation part. Organic fertilizer equipment needs fermentation compost windrow turner, crusher, mixer, fertilizer granulator, dryer, cooler, screening machine, coating machine, packaging machine, conveyor and other equipment. Organic fertilizer production plant cost about 250000 yuan.

The organic fertilizer production plant cost is hundreds of thousands to millions.

1. Fermentation compost windrow turner: it can ferment and turn the materials in the fermentation process.

2. Crusher: crushing high humidity materials and other raw materials in the organic manure production.

3. Mixer: to mix a variety of raw materials.

4. Granulator: Granulation of mixed materials; easy to separate and package.

5. Dryer: drying granular materials with certain humidity.

6. Cooler: it can quickly cool the dried materials and increase the production efficiency.

7. Screening fertilizer production machine: screen and grade the finished fertilizer.

8. Coating machine: the particles are coated outside to prevent the caking of fertilizer.

9. Automatic weighing and packaging machine: quantitative bagging and packaging of finished products.