views

1. Pre feeder: hopper with mechanical vibration, automatic control, timing vibration.

2. Quantitative feeder: frequency conversion speed regulation is adopted to ensure feeding accuracy.

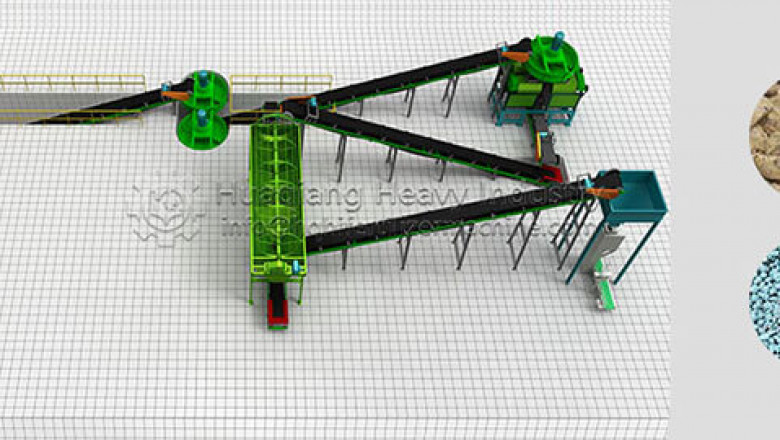

Composition and equipment of the production line of the double roller granulator

Composition and equipment of the production line of the double roller granulator

1. Pre feeder: hopper with mechanical vibration, automatic control, timing vibration.

2. Quantitative feeder: frequency conversion speed regulation is adopted to ensure feeding accuracy.

3. Forced feeding screw feeding hopper: it is composed of variable frequency speed regulating motor, conical screw, mixing blade teeth, conical feeding hopper with mirror window and feeding port. Its function is to further complete degassing and pressure feeding.

4. Rolling mill: it is composed of left and right fixed bearing pedestal and sliding bearing pedestal, frame structure, two alloy steel rolls, two hydraulic cylinders and electric automatic pump station, special reducer for hardened tooth surface and main motor.

5. Fertilizer granulation machine: the crushing and pelletizing chamber is composed of a chopping box, a chopping spindle and a special rotary blade. The motor drives the spindle to rotate at high speed to crush the extruded materials.

6. Vibrating grading screen: with anti blocking device, it is convenient to clean the screen. The crushed powder from the crusher is divided into granular products and recycled powder through the screen.

7. Return auger: conveying the unqualified powder material returned by the vibrating classifier to the feeding elevator.

8. Bucket elevator: the upper and lower sprockets are assembled for conveying materials.

9. Electric control cabinet: it is composed of electric cabinet, variable frequency speed controller, ammeter, voltmeter, indicator light, button switch, voltage transfer switch and other electrical components. All electrical appliances are controlled and operated centrally.