views

General Situation Of The Development Of VGT Turbocharger Control Systems Abroad

International nations have always remained in a leading position in the study and also advancement of VGT turbocharger (variable geometry turbochargers) management systems. The United States, Germany, and Japan have actually developed a range of typical and also sensible variable nozzle turbocharger control systems.

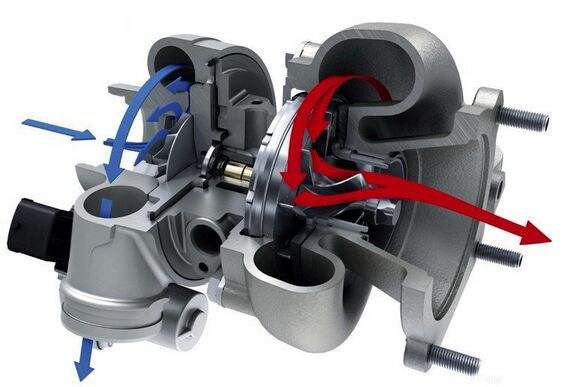

Honeywell established a VGT turbocharger system in the last century, which is generally made up of nozzle vane actuators, PCM shutoffs, air pumps, control systems, sensing units and various instruments. The nozzle vane actuator adopts a diaphragm-type negative pressure actuator, as well as the actuator, is powered by an air pump mounted at the back side of the generator. A PCM valve is installed between the actuator and the vacuum pump to regulate the adverse pressure of the actuator.

The control system sends a control signal to the PCM valve according to the engine sensor signal and changes the unfavourable stress produced by the vacuum pump by changing the time ratio of opening as well as the closing of the PCM shutoff, consequently managing the angle of the nozzle vanes. The control system takes the boost stress as the control target criterion.

To boost the security and also smoothness of the system under non-steady state conditions, a feedforward PI control formula is made use of: the engine speed and also lots are identified under steady-state problems. The nozzle opening load ratio is made use of as feedforward and is also included in the PI control formula to realize the control of the PCM shutoff.

American GM has actually also established a VGT turbocharger system for fuel engines. The system includes an actuator, digital pressure regulator (EPR), electronic vacuum regulatory authority (EVR), digital control device and also sensors.

The distinction between the system diaphragm kind pressure actuator as well as the previous diaphragm kind actuator is that the actuator air chamber is divided right into two components by the diaphragm, and the diaphragm is all at once impacted by the consumption manifold as well as the booster from the air intake manifold prior to the compressor after the throttle valve.

The stress distinction between the two air chambers of the compressed intake manifold pushes the diaphragm to drive the nozzle ring blades to turn, to guarantee that the pneumatically-driven actuator can successfully get rid of the resistance from the nozzle draw rod under numerous functioning problems.

On top of that, the pressure in the two air chambers is regulated by EPR as well as EVR, specifically. The control technique is to very first create a steady-state working problem boost pressure control MAP map and store it in the ECM, compare the existing boost stress with the target boost pressure in the ECM, and also the electronic control package adjusts the control signal according to the distinction to make the execution The controller acts to understand the optimum control of boost high pressure.

Furthermore, Japan Ishikawajima-Harima Heavy Industries Co., Ltd. also applied unclear control to a six-cylinder diesel engine power outfitted with a VNT turbo, making use of a stepping motor to drive the actuator, as well as achieved great control outcomes.

Research Status Of Domestic VNT Turbocharger Control System

Domestic research on VNT turbochargers is a little behind foreign countries, and also there are a couple of systems that participated in this research. Among them, Tsinghua College, Beijing Institute of Modern Technology, Tongji College as well as various other schools have actually done some operations in the VGT control system.

In 1995, Wang Junqiu of the Beijing Institute of Innovation and others created a VGT control system. The system consists of electronic control system ECU, turbine area opening up actuator (torque motor), sensing unit as well as control object J6110Z diesel engine and more.

The system accepts signals such as engine rate, boost stress at the compressor end, as well as variation of the nozzle blade actuator at the generator end. Via a certain formula, the control signal is an outcome to the nozzle blade actuator to transform the rotation angle of the nozzle ring blades, therefore regulating the generator nozzle opening.

In 2000, Ma Zhaochen from the Beijing Institute of Technology as well as others developed a mechanical beginning control system for the VGT matched to the J6110Z six-cylinder diesel engine. The placement of the nozzle ring blade of the supercharger is managed by a swing pole, which embraces the lever concept.

The two ends of the swing pole are the nozzle ring blade and the spring specifically. The equilibrium of the stress distinction across the actuator diaphragm drives the nozzle ring vanes to turn. The style factor of the turbocharger is chosen at the calibration point, at which time the stress of the springtime is balanced with the compressor outlet pressure acting upon the diaphragm.

The State Secret Research Laboratory of Auto Security and Power Preservation of Tsinghua College has created the VGT turbocharger control system on the Volkswagen TDI engine, which is identified by utilizing a stepper motor as the actuator, as well as examining the MAP map with both signals of the engine rate sensor and the accelerator position sensor., obtain the target increase pressure, and carry out PID control.

In the constant state, the PID control with the change of the variable nozzle opening is taken on to accomplish excellent command of the target increase stress. In the transient condition, the control method of PID specifications varies from the consistent state and the introduction of the prediction feature is taken on to improve the response speed of the system in the transient condition. The examination is carried out on the developed software and also the equipment system.

Epilogue

Variable nozzle exhaust gas turbocharging innovation has a wider space than typical exhaust gas turbochargers in regards to power conservation as well as exhaust reduction of inner combustion engines. It is the existing growth direction of supercharging innovation.

Its research and development are of terrific significance to promoting the upgrading of China's VGT turbocharger sector. After decades of technical build-up abroad, the variable nozzle turbocharger is much ahead of China in regards to overall modern technology and also control modern technology, while the research study on variable nozzle turbochargers in my nation is just in the theoretical research study stage.

Honeywell has developed a VGT turbocharger system in the last century, which is primarily made up of nozzle vane actuators, PCM shutoffs, vacuum cleaner pumps, control units, sensing units as well as various instruments. The nozzle vane actuator embraces a diaphragm-type negative stress actuator, and also the actuator is powered by a vacuum pump set up at the back end of the generator. A PCM shutoff is mounted between the actuator and also the vacuum pump to control the unfavourable stress of the actuator.

The two ends of the swing pole are the nozzle ring blade as well as the springtime respectively. The balance of the pressure difference throughout the actuator diaphragm drives the nozzle ring vanes to revolve.