views

Common faults and solutions of disc organic fertilizer granulator

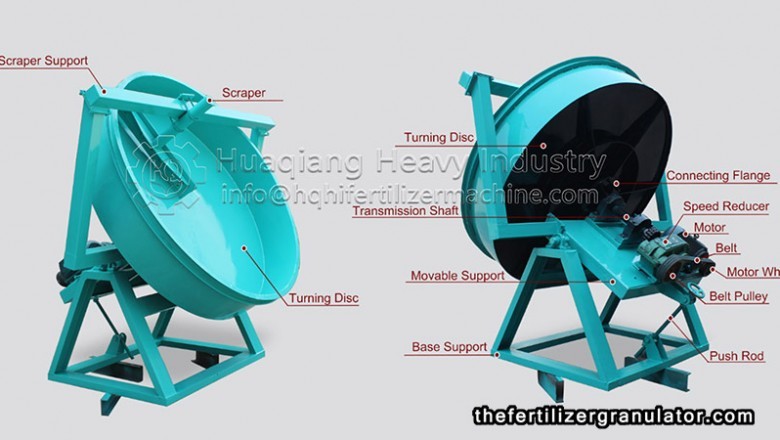

In this big industry of organic fertilizer granulator, there are countless manufacturers of large and small equipment, and the production of disc granulator is also slightly different. Some equipment problems are actually "tire belt". On the other hand: in order to save cost, some organic fertilizer equipment manufacturers choose to install debugging equipment by themselves, which will inevitably encounter various problems in debugging and installation. How to solve the problems of disk granulator in the process of use and installation, Zhengzhou Tianci Heavy Industry Co., Ltd. to list the common fault solutions.

1. Severe vibration of disc granulator body?

Solution: fix the base of granulator firmly, and check whether the gears of the machine body bite normally (some organic fertilizer equipment manufacturers leave "tire belt" fault in the production process).

2. How to adjust the disc inclination?

Solution: in the disc fertilizer granulation process, the control and adjustment of the inclination of the disc granulator in use does not have a specific parameter for your reference, but it should be based on the shaping of spherical particles. The adjustment measure is to adjust the bolt at the bottom of the disc, change the position and angle of the reducer to achieve the purpose of normal use.

3. Intermittent operation.

Solution: this kind of fault is generally caused by bearing damage, disk weight loss, abnormal motor voltage and other reasons. By following the vine and maintaining it in time, the running trouble of disc granulator machine for fertilizer can be eliminated quickly.

4. The material is difficult to form

Solution: in addition to the subjective factors of raw material composition, the particle forming of disc fertilizer pellet machine also has an important relationship with the fineness of raw material, water content, the addition of auxiliary adhesive and the angle of disc operation. These problems should be constantly tried, according to their own material situation to achieve their own ratio, do some improvement, we can achieve our expected value.

5. The particles produced are not uniform

Solution: the treatment of this kind of problem is divided into two parts. Improve the moisture content and control the size of molding particles. Then, through screening after drying, we can narrow the scope of our choice.