views

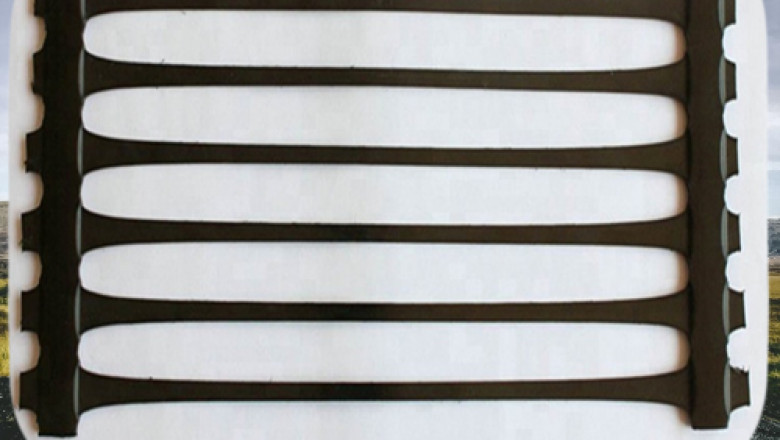

Uniaxial geogrid is called uniaxial because the geogrid is more hearty in the machine heading than in the cross-machine bearing. A simple method for recollecting this is that it implies the geogrid's "strength is long," so it ought to be carried out opposite to the substance of the wall or incline to the correct length in light of the designed plans. Uniaxial geogrids are generally developed of polyester yarn with a PVC or similar covering. A biaxial geogrid is a geosynthetic compound made from polypropylene polymers and is essentially used to support and settle soils. They are made through a progression of techniques, including crossway extending, lengthway extending, and expelling. This creation cycle guarantees that all the geogrids have high strain obstruction and elasticity. Singhal Industries Private Limited is the largest manufacturer of Biaxial Geogrid & Uniaxial Geogrid.

How do biaxial geogrid work?

If the dirt in the space where you will add a thick burden is too delicate, the strain will drive the dirt to twist. A Geogrid will assist with getting the dirt by compacting the total, which improves the bearing limit of the bare ground. Simply put, it reinforces the ground and prevents it from vanishing in heavy rush hour gridlock, forestalling rutting - and so on.

Dissimilar to when the heap is acquainted with the dirt alone, the geogrid powers the weighty burden's strain to be spread over the whole surface region of the framework due to the subgrade having strength in the two headings. It's a comparative justification for why, on the off chance that you were strolling in a dangerous situation, you are in an ideal situation setting down to spread your body weight over a bigger surface. It's a similar rule here.

This implies once the Singhal Industries Private Limited Biaxial geogrid is set out and the weighty burden is set up, the dirt underneath the matrix compacts, and the subgrade's solidarity is additionally improved. This implies that it is exceptionally savvy by saving both work and upkeep costs. Functions admirably for ranch tracks and so on or country paths that trucks drive all over. It assists with halting the trenches brought about by the load on the tires, which in any case would require standard topping off.

How does uniaxial geogrid work?

The Singhal Industries Private Limited Uniaxial geogrids are soil support commonly utilized in development and agricultural applications. They are produced using sand, residue, and dirt and are usually estimated in pounds per square foot. They can be utilized to settle soils and work on their dampness, and supplement maintenance. The most commonly utilized uniaxial geogrid is a substantial support network, which includes a total or a substantial lattice. These cross-sections support the dirt and work on its compressive strength. Geogrids are utilized as soil stabilizers to balance out the dirt and decrease settling or breaking. Both Biaxial Geogrid & Uniaxial geogrid are used for construction.

Uses of biaxial geogrid

PP Biaxial geogrid applications in asphalt and streets comprise subgrade improvement, building the base course, sub-base, and surface courses. The outward relocation of railroad counterweight is captured, and the settlement is decreased when supported with the delicate geogrids subgrade. The stiffer geogrids perform better than adaptable geogrids as the last option rapidly responds to the applied burden.

Biaxial Geogrids are utilized for settling the refill in holding walls. The soundness of the world's holding wall relies upon the rubbing point. Creep and stress unwinding properties influence the presentation of geogrids in a holding wall. In the holding wall, high-strength geogrids should be given, or the geogrid support separating should be diminished.

The PET Biaxial geogrid support in slant impacts the slant deformity and security. The bearing limit principally relies upon the length of the geogrid. Because of higher rigidity and longer length, there is a ruin in the dislodging of the earthen dams and an expansion in the well-being factor.

Uses of Uniaxial Geogrid

HDPE Uniaxial Geogrid can be utilized in various ways. You would utilize Uniaxial Geogrids to uncover and clear the dirt over it. This would be finished to make an establishment for structures or even a street. Uniaxial Geogrids are, in many cases, utilized in building streets since they can convey weighty loads far superior to different materials like blocks or cement. The massive size of Uniaxial Geogrids permits them to endure longer and confront more pressure. Like this, they are appropriate for voyaging streets, assuming they have been based on stony ground.

Uniaxial Geogrids are significantly more steady than Strain Geogrids. They can endure pressure and pressure similarly and take on a great many pounds without breaking. Making geogrid includes laying the surface layer exceptionally level to be completely smooth. Compressive pressure can likewise influence the respectability of a Strain Geogrid, yet it is far more doubtful to cause breaks than elastic pressure.

Final words

The Singhal Industries Private Limited is one of the most amazing biaxial geogrid manufacturer. Both biaxial geogrid & uniaxial geogrid are regularly utilized in establishment works. The essential condition to accomplish excellent security is the interlocking limit of geogrid and totals. The vibrations are very much constrained by geocell support.