views

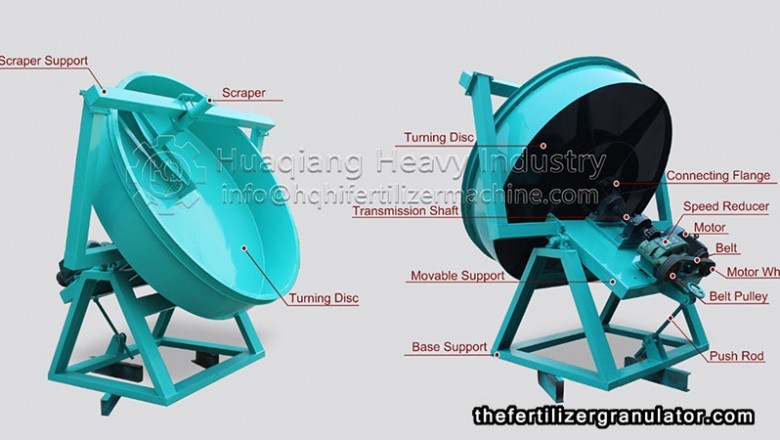

Structure characteristics and operation precautions of disc organic fertilizer granulator

Disc organic fertilizer granulator is a new type of inclined plate granulator, with granulation rate up to 90%. The reducer and motor are driven by flexible belt, which can start smoothly, slow down impact force and improve the service life of the equipment. The fertilizer granulator adopts multiple radiating steel plates to strengthen, which is firm and durable, with no deformation, thickening, weighting and solid base design, and does not need anchor bolt fixation The main gear of granulator adopts high frequency fire, and its service life is doubled. After anti-corrosion treatment, the pelletizing plate is durable and highly praised by users. It is an ideal choice for users. The fertilizer pellet machine is an applicable technology promotion project of environmental protection in China.

The structural features are as follows:

1. The bottom of the pelletizing plate is strengthened by several radiating steel plates with high strength and rigidity;

2. Transmission gear adopts high frequency quenching treatment, which has long service life;

3. The reducer and motor are driven by flexible belt, with stable starting and small impact force;

4. The transmission system is equipped with a bridge device to reduce the direct impact between the gear and the reducer, and improve the operation stability of the granulator machine for fertilizer and the service life of the main parts;

5. The unique non power combination scraper device reduces the auxiliary power consumption

Precautions for operation of disc organic fertilizer granulator:

1. It is forbidden to enter the material with iron.

2. Apply yellow dry oil on the gear before starting the fertilizer granulation process.

3. The gear oil must be added once before the reducer is used in production. The gear oil should be changed every four months.