views

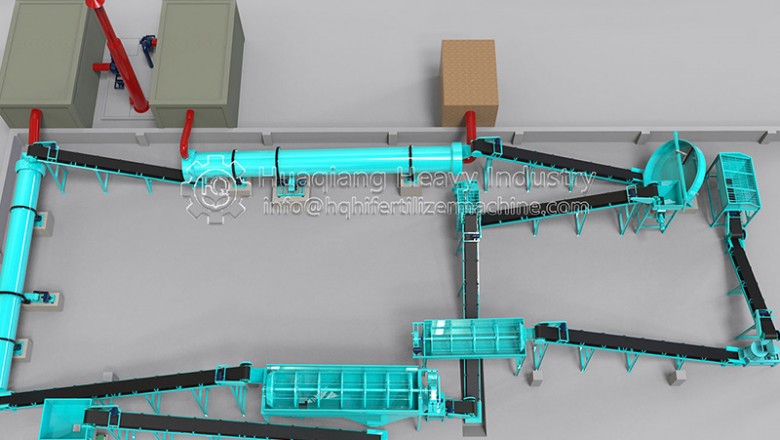

Process of cow manure organic fertilizer granulator

After the organic fertilizer granulator makes the cow dung into granular fertilizer, it is beneficial to improve the organic matter and fertility of the soil, and improve the soil physical and chemical environment and microbial environment. However, if the uncomposted manure is directly applied to the farmland, it will consume the oxygen in the soil and generate high temperature, which will burn the roots of the crops and produce pathogenic bacteria and harmful substances. Pollution. Therefore, cow dung must be used after composting, stabilization and harmless treatment.

The organic fertilizer granulation process: pour the raw materials into a mixer and mix them, mix them evenly and smash them, and use the belt conveyor to enter the granulation plate; after the granulation is formed, they are sent to the dryer for drying, and then transported to the The cooler cools and the water content reaches below 6%. After cooling, it is screened. The large particles are crushed into fine materials by the return crusher. The fine materials enter the disc fertilizer pellet machine, and the coarse returned materials enter the granulator after crushing. Pack directly.

Organic fertilizer (granulator machine for fertilizer product) enhances the resistance of crops and reduces or prevents the occurrence of diseases. After the organic fertilizer is applied to the soil, it can enhance the water storage capacity of the soil. In the case of drought, it can enhance the drought resistance of crops, and it can also loosen the soil, improve the ecological environment of crop roots, enhance root vitality, and increase crop tolerance. Reduce plant mortality and improve the survival rate of crops.