views

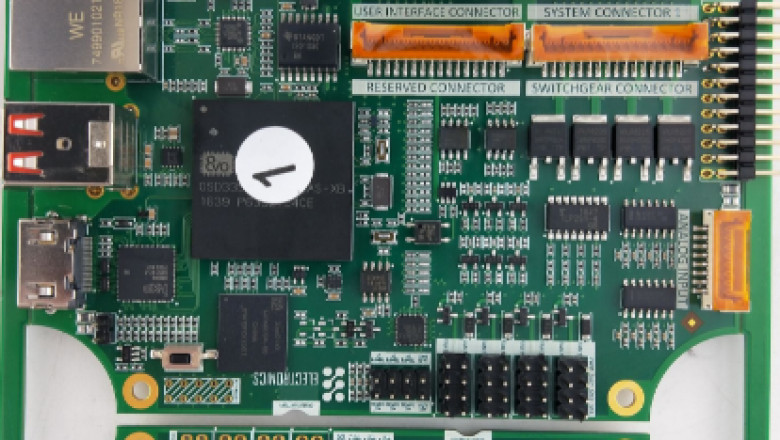

Flexible circuits are becoming more common in almost every electronic and electrical product, and they are expected to continue to grow. This type of circuitry is the fastest-growing segment of interconnection products, and this growth should continue to be supported by the increasing number of participants and their IC packaging needs. According to a recent report by Techsearch International, the market for standard flex circuits could reach $3.4 billion by 2023. By 2024, it is expected that high-density IC packages will require a higher-density flex circuit.

While it can be challenging to determine the exact amount of a flex-printed circuit, there are a few key factors to keep in mind as you work with a flex-printed course. First, your bill of materials is a vital tool. It helps you understand precisely what materials are necessary for a certain flex circuit and is an excellent tool to communicate with different departments involved in the flex circuit manufacturing process. It also acts as a reference for quotes and allows for the traceability of materials.

Another advantage of flex PCBs is that they are lightweight compared to rigid PCBs, allowing for up to 75% weight reduction. The thin polyimide or polyester material that flex PCBs are made from can be as light as twelve to 120 microns, and the conductive material traces are etched onto the surface of the flexible circuit board. There are as many layers of flex circuit as required, and they are usually protected with an overlay.