views

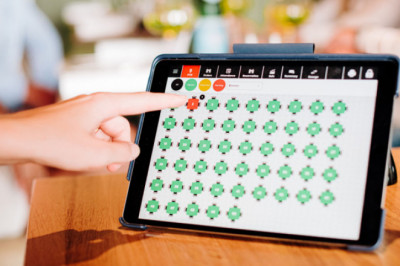

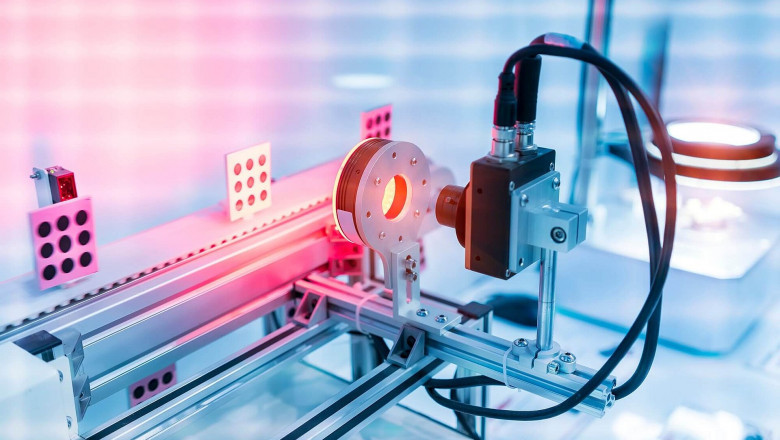

To precisely detect surface faults and characteristics, surface inspection uses angled illumination and sophisticated cameras. Web products, coated surfaces, and complicated materials like the display glasses on tablets and smartphones are all inspected using Surface Vision And Inspection techniques or devices. It finds very small blemishes, flaws, or holes in items. Automatic inspection systems, cameras, and sensors from the core mostly handle surface inspection. It was adopted for numerous purposes, including visual inspection, package inspection, error detection, and quality assurance.

Surface Vision And Inspection is a non-destructive technique for seeing potential flaws on an object's surface while it is still in the production cycle. It uses specialised cameras, lighting systems, and other equipment to accurately and automatically detect flaws. Currently, it is widely used to verify that manufactured goods satisfy the anticipated aesthetic features in a variety of end use sectors around the world. For instance, it is applied in the automotive sector to examine the texture, roughness, and proper finishing of unsold vehicles.

Read More@ https://cmibloginsight.blogspot.com/2022/08/surface-vision-and-inspection-enable.html