views

Mining Equipment Industry Procurement Outlook

A rise in urban population increases the demand for natural resources is expected to surge the demand for mining, which in turn, fueling the procurement need for mining equipment. Mining is of two types; surface mining and underground mining. These two mining types have separate lists of mining equipment from each other.

-

Surface mining: It is the most common mining type for non-fuel minerals. There are three ways to mine on the surface. These methods include quarrying, open-pit mining, and strip mining. The major equipment needed for surface mining is a dragline excavator, excavator shovel, bucket-wheel excavator, wheel tractor scrapers, bulldozer, mining Truck.

-

Underground mining: Underground mining is used for minerals, ore, metals, or other goods located deep underground. Room and pillar mining, retreat mining, and blast mining are the three main underground mining methods. Major equipment used in underground mining is mining drill, underground loader, crane lift, shotcrete machine, and longwall mining.

All mining equipment can be categorized into three major categories based on their applications.

-

Extraction involves drilling, blasting, or digging to remove materials from the mine site.

-

Material handling includes sorting and loading materials to a waste area or the processing site.

-

Material processing involves grinding, separating, crushing, refining, and smelting mined goods at an off-site plant to turn them into finished products.

Grab your copy, or request for a free sample of the “Mining Equipment Industry Procurement Intelligence Report, published by Grand View Research” for In-depth details regarding supplier ranking and selection, sourcing, and pricing criteria & strategies.

Demand Outlook

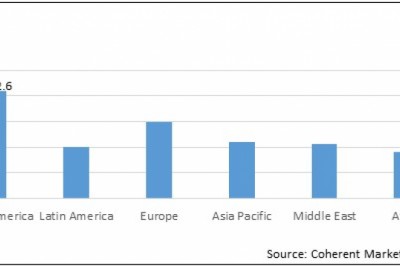

The global mining equipment market is valued at USD 160 billion in 2020 and it is expected to grow at a CAGR of 12% from 2020 to 2027 due to the rising demand for metal mining, coal mining, and mineral mining. The metal mining application segment dominated the global mining equipment industry owing to an increase in the hauling of metal deposits and high demand for precious metals. Furthermore, iron and copper mines in South America and Australia are procuring additional equipment deliveries, which is expected to trigger the growth of this application segment. APAC countries like India and Australia are leading the global mining equipment market due to high demand and multiple government initiatives. For instance, the Government of India has approved 100% FDI for the exploration of metal and non-metal ores. Moreover, the Ministry of Steel is aiming to double the steel production capacity to 300 million tons by 2030.

Cost Drivers

Each mining equipment is made of different materials based on their application. The cost of raw material is one of the important aspects of mining equipment production cost. However, the cost of procuring raw materials to manufacture mining equipment is somewhat similar across the world. Hence, manufacturers try to increase profit margin by outsourcing the production activities to low-cost countries like India and China.

Add-on Services provided by Grand View Research Pipeline:

-

Should Cost Analysis

-

Rate Benchmarking

-

Salary Benchmarking

-

Supplier Newsletter