views

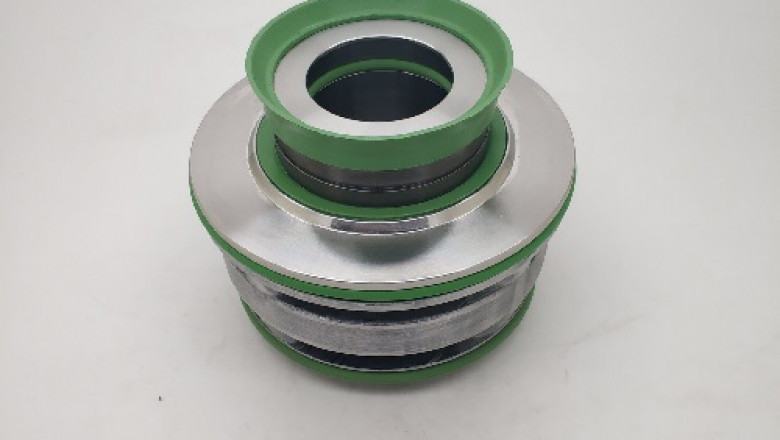

Mechanical seals are quite beneficial in different applications including use in pumps. But For those who have recognized that your seals manage to are unsuccessful normally and a lot quicker for instance, there could be things you are accomplishing Improper. The fails could possibly be due to the set up and collection errors or they may be because of poor managing with the seals. By shelling out near focus to the selection, set up and functions try to be able to continue to keep the fails small.

1. Hardly ever let your pump to run dry

If you allow the pump to operate dry, Then you certainly possibility harmful the mechanical seal which is set up. The mechanical seals knowledge thermal shock and shatter in a few seconds and it truly is hence critical to make certain that the pump is functioning underneath the correct problems to prevent this sort of occurrences.

two. Discover techniques to lower vibration

Pump vibration is an additional bring about for seal fails. The vibration can result from inappropriate alignment, pump imbalance and functioning the pump on BEP that may be also considerably off still left or right on functionality curve. When it occurs then it finally ends up hurting equipment and destroyed seals or shortened life of the seal is what you have got as your effects.

three. Don't hammer couplings on to the shaft

Hammering is the worst issue you are able to do along with your mechanical seals. The seal faces are fragile and after you pound couplings onto your pump shaft, Then you definately will definitely find yourself harming the mechanical seal. Use substitute usually means to place the couplings so the seal can keep on being intact and in prime condition.

4. Understand how to work your pump

Improper dealing with with the pump will generally journey the motor and twist the shaft that resulting in orbital movement that impacts inside pieces and results in seal failure. You will also shorten bearing lifetime when you so not stick to start out-up procedures. Improper installation with the seals also needs to be prevented because they might turn out harming elastomers and cause other concerns. The flat character or perhaps the seals make them delicate and as a result care ought to be taken when dealing with them.

5. Use mechanical seal flush strategies adequately

Your seal will only be entire when you have a coordinating flush strategy. Without the flush program, you'll get contaminated and dewatered products which bring on too flygt mechanical seal much warmth and erosion on seal thus shortening its everyday living.

six. Pay attention to seal product and kind

Majority of mechanical seal fails are as a result of choosing the Incorrect seals and seal products. Very poor substance decision will only signify that the seal will not likely maintain your reason of use. You thus really should take into consideration your functioning ailments and non-system things to do like acid flushes, steaming and cleansing when building your collection. The fabric of the seal as well as the seal sort must match With all the liquid they will be sealing in otherwise you can facial area issues with your functions. There is always a correct seal for every specified software so discover the most suitable for yours.