views

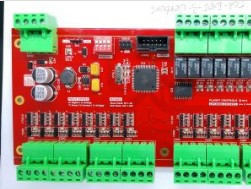

Electronic components for electronic gadgets and equipment are manufactured by electronic board manufacturers. This is a process wherein different components are joined together to form circuits. The various components include microprocessors, resistors, capacitors, diodes, transistors, LEDs, and others. To make an electronic gadget or equipment function properly, all these components must work well together as a team. The circuits made through this process are highly efficient and have a long life.

Most circuit boards produced today are made of high-quality metals such as copper, silver, tin, or steel. High-quality electronic circuit boards are manufactured with special properties that make them durable, conductive, and non-magnetic. Because of these properties, electronic board manufacturers rarely have this kind of heavy copper material in inventory (especially the pure copper thickness > 4oz). Instead, they often use other alloys such as aluminum or tin. Since these other metals are cheaper and have similar conductivity levels, they cost less than pure copper.

The use of nickel-based electronic board manufacturers in their products is a sign of poor quality. These nickel-based components are unstable and conductive even under extreme heat and temperature. They can also corrode easily. Other manufacturers of other kinds of electronic components such as copper PCB raw materials may use trace amounts of nickel in their boards but it still does not qualify as conductive or durable as nickel. Some manufacturers may add small amounts of traces of nickel but the entire panel has to be pure in conductivity and thickness.

Many consumers are concerned about the environment when using electronic parts like microprocessors, LEDs, and capacitors. In fact, many environmentalists and environmental groups are lobbying for changes in how industries use materials that cause global warming. By using cheap plastic-based PCBs, electronic board manufacturers are taking advantage of this concern. Consumers may want to consider industrial electronic circuit boards that are made from recycled plastic or ones made from reclaimed wood, which is much more environmentally friendly.

The use of low-cost PCB raw materials in circuit boards has its place. It can be cheaper to produce due to the economies of scale from the lower volume of orders. It can also be easier to find materials like copper and other metal compounds because of recycling. But by mass-producing cheaply made circuit boards, companies can lower the standards for quality. Consumer protection agencies have begun legal suits against companies that use counterfeit or recycled parts in their merchandise. This is a very real concern that must be addressed if manufacturers want to maintain the trust of their consumers.

Some PCB manufacturers have already taken steps to improve their quality control. For instance, one company changed from brass-to-copper alloys for their printed circuit boards. By using these alloys, they have been able to reduce the amount of lead and cadmium that would normally be found in the composition. In addition to these efforts, they have used other techniques to make sure that contaminants are removed from their finished product.