views

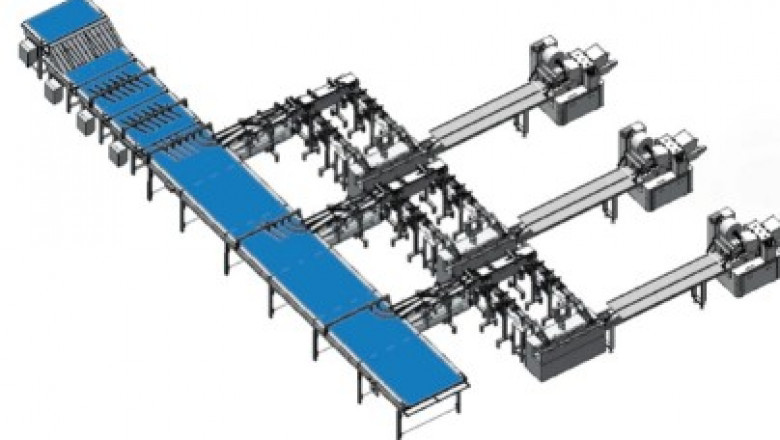

A food packaging production line needs to be space-efficient and ergonomic. It should be arranged in a way that allows for easy access by people, and space for storage and waste management. It should be able to accommodate primary and secondary packaging, as well as storage for finished products. It must be easy to clean. In addition, the layout must be suited to the product to be packed and stored. A good production line should be a combination of these components.

A food packaging production line has three major parts: the automatic packaging machine, transmission storage device, and labeling machine. The sorting unit is the most important process equipment, and its functions are varied. The conveying unit is used to distribute the products and place them in an orderly queue. The labeling machine is an auxiliary device. It performs a specific function, and the conveyor belt is necessary for putting products into the packaging.

The packaging machine that completes the food packaging production line is an automatic packaging machine. It is the basic process equipment. It has many types, including small flow wrapping machines, vacuum packages, weighing packaging machines, multi-functional machines, and many more. The equipment used is made by Foshan Ruipuhua Machinery Equipment Co., Ltd.. in Foshan, China. The company has nearly 20 years of experience in automation secondary-packaging machinery.

A food packaging production line includes a filler and a vacuum system. The filler is a common source of lost productivity. It needs special care and maintenance and is slower than the other parts of the line. Using an accumulation table can help improve throughput. In addition, the automatic control system completes a defined cycle and achieves a predetermined quantity and quality. The auxiliary devices include a data encoder, a conveyor belt, and a labeling machine.

There are many different types of packaging machines. A food packaging production line can include flow wrapping machines, vacuum packaging machines, and weighing machines. Other types of equipment are multi-functional, automatic machines, and servo-sorting tailstocks. Each of these machines has a different function, and the overall efficiency of the operation depends on how well it is used. It is a highly versatile system, with many advantages. This machine is very flexible and can be easily adapted to meet the requirements of many kinds of businesses.

The food packaging line is a comprehensive system. It consists of three major parts: an automatic packaging machine, a transmission storage device, and an automatic control system. The first part of the line is the automatic packaging machine. Its functions are a vacuum sealer, a weighing machine, a weighing device, and a labeling machine. It also includes the conveyor belt and the servo-sorting tailstock.