views

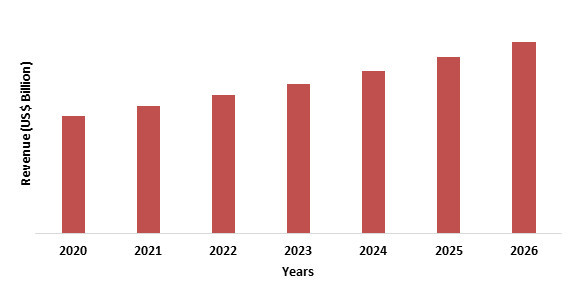

Fiber Cement Market size is forecast to reach $20.5 billion by 2026, after growing at a CAGR of 4.8% during 2021-2026. Fiber cement is a composite materials compound with lignocellulose reinforcement that is composed of sand, Portland cement, silica sand, and cellulose fibers. The demand for fiber cement can be credited to the growth in demand for fiber cement products for construction activities, with the escalation in government rules on consumption of asbestos, across the globe. Factors such as excessive demand for environmentally friendly and sustainable building materials are influencing the demand for fiber cement products like slates, Corrugated sheets, false ceilings, flat sheets, and others. The global fiber cement market can hit upon an extensive range of applications through the residential and non-residential applications which mostly include exterior wall cladding, roofing, and building facades. Fiber cement producers are enduring to generate innovative techniques for customers to purchase their products further effortlessly.

COVID-19 Impact

The COVID-19 pandemic has had an immediate impact on the world economy and that impact goes across all industries, including Fiber Cement. The construction sector was one of the sectors that had to carry the most terrible impact of COVID-19, as it was previously fighting a liquidity crisis as an outcome of the non-banking financial institutions in the financial sector for more than a year. Many projects endured in the unfinished stages because of the lack of funds. Those that were finished, remained unsold, because of changing buyer preferences which has indirectly impacted the fiber cement market growth. Although, the COVID-19 pandemic remains highly volatile and continues to evolve, and the full impact of the pandemic on the Company’s business and future financial performance remains uncertain.

Fiber Cement Market Report Coverage

The report: “Fiber Cement Market- Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Fiber Cement Industry.

By Raw Materials: Sand, Portland Cement, Cellulosic Material, Silica, and Others

By Product Type: Slates, Corrugated sheets, , Planks, Partition walls, Window sills, and Others

By Application: Roofing and Façade, Exterior (Cladding, Siding, Soffits, others), Interior (Acoustic panels, Mezzanine floor, others), Fences, and Others

By End-Use Industry: Building and Construction [Commercial (Hospitals and Healthcare Infrastructure, Educational Institutes, Hotels and Restaurants, Banks and Financial Institution, Airports, Office Buildings, Others)], [Residential (Independent Homes, Row Houses, Large Apartment Building)], Infrastructural, and Others

By Geography: By Geography: North America (USA, Canada and Mexico), Europe (UK, France, Germany, Italy, Spain, Russia, Netherlands, Belgium, and Rest of Europe), APAC (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, Rest of South America), and RoW (Middle East and Africa).

Key Takeaways

- Asia Pacific dominates the Fiber Cement Market owing to a rapid increase in the Automotive and construction sector.

- The market drivers and restraints have been assessed to understand their impact on the forecast period.

- The report further identifies the key opportunities for growth while also detailing the key challenges and possible threats.

- The other key areas of focus include the various applications and end-use industry in Fiber Cement Market and their specific segmented revenue.

- Due to the COVID-19 pandemic, most of the countries have gone under temporary shutdown, due to which operations of Fiber Cement related industries have been negatively affected, thus hampering the growth of the market.

<span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi"="" style="box-sizing: border-box;"> Figure: Fiber Cement Market Revenue, 2020-2026 (US$ Billion)

For More Details on This Report - Request for Sample

<span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi"="" style="box-sizing: border-box;">Fiber Cement Market Segment Analysis - By Raw Materials

Portland Cement dominates the Fiber cement market growing at a CAGR of 4.2% over forecast period. Portland cement is manufactured by combining various elements including calcium, silicon, iron, aluminum, and other ingredients. Portland cement is of two type’s namely Ordinary Portland cement (OPC) and white Portland cement. Increasing demand in making fiber cement is expected to contribute to the demand over the next seven years. Moreover, the low cost and easy availability of the materials required for manufacturing Portland cement including limestone, naturally occurring materials, and shale is expected to spur market growth.

<span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi"="" style="box-sizing: border-box;">Fiber Cement Market Segment Analysis - By Product Type

Corrugated sheets dominated the Fiber cement market holding share of 34%. They are a trendy siding and roofing best for agricultural and commercial buildings, due to their strength and durability. Corrugated sheets are generally used in the residential sector in prominent amounts in the form of roofing and siding options. They are durable, weatherproof, and will not rot or decay. Currently, this type of roofing is used as an alternative for asbestos sheeting, being safer and often more affordable in comparison. As per the pollution levels prevailing where they are installed, corrugated sheets have to be maintained every 5-10 years. Completely durable and eco-friendly, these roofing sheets are ideally used for protecting garages, porches, and sheds. As the consumers being dissatisfied with the available conventional options and looking for more value from their investments in corrugated sheets. This, in turn, has created a higher demand for corrugated sheets in the Fiber cement market.

<span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi"="" style="box-sizing: border-box;">Fiber Cement Market Segment Analysis - By Application

Fiber-cement Siding held the largest share of 38% in the Market in 2020. Siding is a construction material used for concealing the outside of residential and commercial buildings. Fiber cement siding grasps on the look of wood or masonry but has concrete toughness because it contains a mixture of water, wood pulp, fly ash or silica sand, and Portland cement. Fiber cement siding has become popular for its durable, but flexible nature. The Cleveland-based research firm, for instance, estimates that the residential market will justify the widely held demand expansions for fiber cement in the next four years. The furthermost significant profits will originate from the residential renovation market, as homeowners progressively replacing the existing siding with fiber cement to perk up the exterior performance or to save time and money on maintenance.

<span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi"="" style="box-sizing: border-box;">Fiber Cement Market Segment Analysis - By End-Use Industry

Building and Construction dominates the Fiber Cement Market growing at a CAGR of 6%. The escalating demand for fiber cement in the building and construction industry is likely to drive market growth during the forecast period. The increasing disposable incomes of individuals paired with the higher standards of living are anticipated to be the key drivers for the growth of the building and construction industry. As the future of the global construction industry looks good with opportunities in residential, non-residential, and infrastructure which is set to rise to US$12.9 trillion by 2022, driven by Asia Pacific, Africa, and the Middle East. For instance, the Indian government in December 2020 announced key infrastructure projects such as National Highway projects worth approximately US$ 4.99 billion in India [DK3] which will result in the indirect escalating demands in the Fiber cement industry. Also, the existence of several raw material contractors are likely to continue their development in fiber cement market size in the construction sector.

<span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi"="" style="box-sizing: border-box;">Fiber Cement Market Segment Analysis - Geography

Asia Pacific region held the largest share in the Fiber cement Market in 2020 up to 42% followed by North America and Europe. Asia-Pacific contains some of the fastest-growing economies in the world, and each jurisdiction is focused on creating a pipeline of opportunities for the development of infrastructure. Factors such as improving the global economy, growing construction sector, particularly in rapidly-growing countries such as China and India, huge foreign investments, and growing awareness about the ill effects of using asbestos are expected to boost the market for fiber cement. In addition, stricter norms regarding the use of asbestos cement in the construction of residential and commercial buildings have made it mandatory for builders and related authorities to look for alternatives such as fiber cement. In India, some of the recent initiatives, such as the development of 98 smart cities and Urban Rejuvenation Mission for which Rs. 139 billion (US$ 1.93 billion) has been allocated, and In China, 26 infrastructure projects with a total expected investment of 981.7 billion yuan (US$142 billion) in 2019 were approved. Rail projects in Chongqing, Kunming, Chengdu, Zhengzhou, and Xian top the list, which also includes the expansion of Xianyang International Airport is expected to provide a major boost to the sector. On the other hand, the German Ministry of Transport and Digital Infrastructure is planning to invest EUR 300 million in future technologies, such as electric mobility or automated and networked driving for electric vehicle charging infrastructure, which, is likely to positively influence the market. Aided by suitable Government foreign policies, several foreign players such as Lafarge-Holcim, Heidelberg Cement, and Vicat have invested in the country in the recent past. A significant factor that aids the growth of this sector is the ready availability of raw materials for making fiber cement.

Fiber Cement Market Drivers

Alternative for Asbestos and Eco-friendly in Nature will Drive the Fiber Cement Market

Asbestos is a naturally occurring fibrous silicate mineral and was used as a building material. A partial ban on an asbestos product by almost 55 countries worldwide according to the International Ban Asbestos Secretariat, due to its well-known health and safety hazard. Restrictions on the uses of asbestos products have made the manufacturers turn their heads to fiber cement market products as an alternative as for asbestos and fiber cement is almost the same. Both of them are not soluble in water, resistant to fire, and work as insulation because of their thermal stability. But unlike asbestos, fiber cement comes to eco-friendliness. It’s the main reason why fiber cement has become so popular. Regular cement requires a lot of water during production, while fiber cement relies on recycled materials and consumes fewer resources. With water crises in certain areas throughout the world, using materials that reduce water usage is necessary. The banned on the Asbestos product has made the demand likely to grow in the Fiber cement market

Commercial buildings with fiber cement exteriors

The design of commercial buildings is tied up with aesthetics. Fiber cement cladding is receiving a lot of attention in this regard. While many different choices abound with varying degrees of weight, thickness, and ease of installation, this product has emerged as a very appealing solution in many cases. Building materials are tested to the ASTM E-84 standard for surface burning characteristics, and fiber cement cladding, for example from Nichiha Corporation, a known player qualifies as a Class A cladding material since it doesn't easily ignite or spread flames. In fire-prone regions like the U.S. Southwest, these materials offer serious protection, along with plenty of options for style. Fiber cement cladding is a durable solution for building owners for benefits beyond style. It pre-paint option has a greater resistance to fading from UV rays and chipping. It can withstand very hot and sub-freezing temperatures. This means an even coverage and vibrant color that will last for years. Fiber cement market product demands are escalating due to its climate-friendly, fire resistance, and durable nature and are likely to grow in the forecast period.

Fiber Cement Market Challenges

The problem in installation of the Fiber cement

Fiber cement can be brittle before being installed on the wall. Awareness of the types of nails and guns is necessary to prevent blowouts at the point of fastening on the panel. Cutting fiber cement siding produces respirable crystalline silica, a known human carcinogen. Inhaling excessive silica can lead to silicosis, lung cancer, and COPD. Installers must take precautions to protect their health while installing fiber cement. Factors like installation, maintenance, and non-environment friendly are hampering the growth of the fiber cement market.

Moisture Problems with Fiber Cement Siding

Manufacturers have confronted a number of class-action lawsuits from customers whose homes underwent moisture allied damage. Because this material is porous, it can also absorb water through the cut edges. This water can then initiate the result to crack or splits. Moisture can also ground mold or mildew in the sheathing. Fiber cement also requires an extensive duration to dry, unlike wood siding which dries quickly. This amplifies the problem during times of extended heavy rains or snow. Close attention needs to be paid to all required gap clearances. Any violation of the instructions can create serious moisture concerns.

<span lang="EN-US" calibri",sans-serif;="" mso-ascii-theme-font:minor-latin;mso-hansi-theme-font:minor-latin;mso-bidi-font-family:="" "times="" new="" roman";mso-bidi-theme-font:minor-bidi"="" style="box-sizing: border-box;">Fiber Cement Market Market Landscape

<span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;mso-fareast-font-family:="" calibri;mso-fareast-theme-font:minor-latin;mso-hansi-theme-font:minor-latin;="" mso-bidi-font-family:"times="" new="" roman";mso-bidi-theme-font:minor-bidi;="" color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Fiber Cement Market. Major players in the <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:minor-latin;="" mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;mso-hansi-theme-font:="" minor-latin;mso-bidi-font-family:"times="" new="" roman";mso-bidi-theme-font:minor-bidi;="" color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Fiber Cement <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Market are

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">James Hardie Industries PLC (Ireland)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Nichiha

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Alpha Roofing Industries

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">LLC (US)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Allura (US)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Cembrit Holding A/S (Denmark)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Shandong Cement (China)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">CSR Limited (Australia)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Etex Group NV (Belgium)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">Toray Industries Inc. (Japan)

- <span lang="EN-US" calibri",sans-serif;mso-ascii-theme-font:="" minor-latin;mso-fareast-font-family:calibri;mso-fareast-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"times="" new="" roman";="" mso-bidi-theme-font:minor-bidi;color:black;mso-color-alt:windowtext"="" style="box-sizing: border-box;">American Fiber Cement Corporation (US).

Acquisitions/Product Launches

- In February 14, 2019, James Hardie Building Products Inc. introduced three new products HardieSoffit VentedPlus Panel and HardieBacker Cement Board with HydroDefense Technology. HardieSoffit VentedPlus Panel, which surpasses code requirements for roof airflow, and saves time and money on installation by reducing the need for additional venting. HardieBacker Cement Board with HydroDefense Technology is the industry's first and only waterproof cement backer board, offering superior performance, easy installation, and unparalleled tile adhesion. This strategic initiative is likely to outgrow the development of its fiber-cement business. Besides, the initiative has

For more Chemicals and Materials Market reports, please click here