views

Electrical Steel Lamination Market:Overview

Electricalsteel is special-purpose steel customized to obtain specific magneticproperties such as low core loss, small hysteresis area, and high permeability.Electrical steel is mostly produced in the form of cold-rolled strips that areless than 2 mm in thickness. These strips are cut into desired shapes, whichare stacked together to form laminated cores of the transformer as well as therotor and the stator of electric motors. The cut pieces of laminations can befinished by a punch and die, or by a wire electro-discharge machining (EDM).

Electrical Steel Lamination Market: Drivers & Restraints

The methodof producing a material in several layers, so that the material attainsimproved strength, insulation, stability, appearance, and other qualities, isknown as lamination. Processes for lamination differ depending on the type ofmaterial to be laminated. The material used for laminates can be of the same ordifferent type, depending on the process and object to be laminated.Windshields of vehicles are manufactured by laminating a tough plastic filmacross two layers of glass. In transformers and motors steel laminations arecommonly used so as to form the core of coils employed to produce magneticfields.

Anelectrical steel lamination is an iron alloy that consists of up to 6.5% ofsilicone. Usually, commercial alloys contain up to 3.5% of silicone. Increasein the percentage of silicone increases electrical resistivity of steelremarkably. Increased resistivity reduces the eddy current induced and lowersthe core losses. However, the metal hardens and becomes brittle, which affectsworkability of the material. The electrical steel lamination is widely used tolaminate the core of transformers and motors. The transformer core is an ironcore constructed from a highly permeable material made from thin silicon steellaminations. Laminations are aligned together to provide required magnetic pathwith minimum magnetic losses.

RequestSample

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=58821

Electrical Steel Lamination Market: KeySegments

The electricalsteel lamination market can be segmented into non-oriented electricalsteel and grain-oriented electrical steel. Non-oriented electrical steel haslinear magnetic characteristics in all directions. It is mostly used in rotarymachines and iron core materials ranging from large transformers to smallelectric motors. Special processing of steel is carried to control the grain orientation.Non-oriented electrical steel has similar magnetic properties in all directionsand it consists of 2% to 3.5% of silicone. Non-oriented electrical steel isabbreviated as CRNGO (i.e. cold-rolled non-grain-oriented) electrical steel.CRNGO is economical. It is preferred when cost is the primary consideration andefficiency is secondary. It is also used when there is less area to aligncomponents that make use of directional properties of grain-oriented electricalsteel.

Grain-orientedelectrical steel has good magnetic properties in the direction of rolling. Thistype of steel is applied in the manufacture of large, medium, and smalltransformers, reactors, and distribution transformers. It contains around 3% ofsilicone. The processing of steel is carried out in such a way that favorableproperties are developed in the rolling direction, due to the tight grainorientation relative to the sheet. Grain-oriented electrical steel is alsoknown as CRGO i.e. cold-rolled grain-oriented electrical steel. CRGO is mostcommonly supplied in coil form. Then, it is cut into laminations. Theselaminations are used in transformer cores.

MoreTrending Reports

Electrical Steel Lamination Market: Regional Outlook

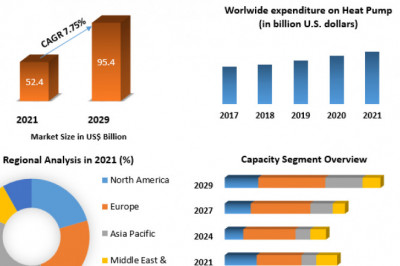

Based onregion, the global electrical steel lamination market can be segmented intoNorth America, Asia Pacific, Europe, Latin America, and Middle East &Africa. Asia Pacific is likely to lead the global electrical steel laminationmarket during the forecast period. The electrical steel lamination market inNorth America is expanding at a significant pace. In Europe, the demand forelectrical steel lamination is estimated to increase in the near future. LatinAmerica and Middle East & Africa are likely to hold a moderate market shareduring the forecast period.

Electrical Steel Lamination Market: Key Players

Some ofthe leading players in the global electrical steel lamination market are UnitedStates Steel, Laser Technologies, Inc., Tempel Steel, Orchid, Sko-DieInc., LCS Company, and Lake Air Companies.

Buy Now

https://www.transparencymarketresearch.com/checkout.php?rep_id=58821<ype=S