views

Corrosion Monitoring Market Report Coverage

The report “Corrosion Monitoring Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Corrosion Monitoring Market

By Technique: Corrosion coupons, Electrical Resistance, Linear Polarization Resistance, Galvanic monitoring, Ultrasonic thickness measurement, Biological monitoring, Hydrogen penetration monitoring, others

<span lang="EN-GB" times="" new="" roman";="" mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;color:black;="" mso-ansi-language:en-gb;mso-fareast-language:en-gb"="" style="box-sizing: border-box;">By Probe Type:<span lang="EN-GB" times="" new="" roman";mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;="" color:black;mso-ansi-language:en-gb;mso-fareast-language:en-gb"="" style="box-sizing: border-box;"> Electrical, Mechanical, Electro-chemical

<span lang="EN-GB" times="" new="" roman";="" mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;color:black;="" mso-ansi-language:en-gb;mso-fareast-language:en-gb"="" style="box-sizing: border-box;">By Industry Vertical: <span lang="EN-GB" times="" new="" roman";mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;="" color:black;mso-ansi-language:en-gb;mso-fareast-language:en-gb"="" style="box-sizing: border-box;">Oil & gas, Petrochemical, Power, Utility, Mining, Construction, Chemical, Pharmaceutical, Food & Beverages, Others

By Geography: North America (U.S, Canada, Mexico), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, South Korea, Australia and Others), South America(Brazil, Argentina and others), and RoW (Middle east and Africa)

<span lang="EN-US" times="" new="" roman";mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;="" color:black;mso-themecolor:text1"="" style="box-sizing: border-box;">Key Takeaways

- APAC is estimated to dominate the market during 2021-2026 owing to emerging economy and high investments in up-gradation of ageing infrastructure through continuous monitoring.

- Increasing demand for power generation and increasing awareness about mitigating accidental risks in oil & gas industries are augmenting the market.

- Corrosion coupon segment is analyzed to dominate the market during the forecast period 2021-2026 owing to cost efficient solutions.

- Oil & gas is anticipated to dominate the market between 2021 and 2026 owing to rising demand of corrosion monitoring solutions for wide range of applications where accidental safety is highly significant.

- High capital expenditure is one of the challenges impeding the market growth.

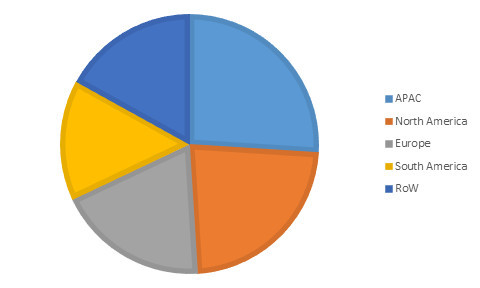

Global Corrosion Monitoring Market Value Share, By Region, By 2020 (%)

For More Details on This Report - Request for Sample

<span lang="EN-GB" calibri","sans-serif";mso-ascii-theme-font:minor-latin;="" mso-hansi-theme-font:minor-latin;mso-bidi-theme-font:minor-latin;color:black;="" mso-themecolor:text1"="" style="box-sizing: border-box;">Corrosion Monitoring Market Segment Analysis – By Technique

By technique, Corrosion Monitoring is segmented under <span lang="EN-GB" calibri","sans-serif";="" mso-ascii-theme-font:minor-latin;mso-hansi-theme-font:minor-latin;mso-bidi-theme-font:="" minor-latin;mso-bidi-font-weight:bold"="" style="box-sizing: border-box;">Corrosion coupons, Electrical Resistance, Linear Polarization Resistance, Galvanic monitoring, Ultrasonic thickness measurement, Biological monitoring, Hydrogen penetration monitoring and others. Corrosion Coupons dominated the market in 2020 acquiring a share of 16.5% and is estimated to dominate the market during 2021-2026 with a CAGR 6.9% due to the rising demand of this cost-effective predictive maintenance tool against premature degradation of assets extending the life of material. Ultrasonic thickness measurement is analysed to be the fastest growing market with a CAGR 10.2% from 2021 to 2026 due to massive and quick adoption of UTM to inspect the metal thickness in wide range of structures including piping, pressure vessels, ship hulls and structural sheet. In April 2021 Qatar Foundation, Research, Development and Innovation announced to develop a smarter version of corrosion coupons embedded sensor to monitor the integrity in pipelines. Such developments are anticipated to steer the market between 2021 and 2026.

Corrosion Monitoring Market Segment Analysis – By Industry Vertical

By industry vertical, Corrosion Monitoring Market is segmented under <span lang="EN-GB" times="" new="" roman";mso-bidi-font-family:calibri;="" mso-bidi-theme-font:minor-latin;color:black;mso-ansi-language:en-gb;mso-fareast-language:="" en-gb"="" style="box-sizing: border-box;">Oil & gas, Petrochemical, Power, Utility, Mining, Construction, Chemical, Pharmaceutical, Food & Beverages and Others. Oil & Gas held the largest market share in 2020 and is estimated to witness low growth with a CAGR 3.3% during 2021-2026 due to increasing demand for Corrosion Monitoring systems to modernize and upgrade aging infrastructure and components through continuous monitoring and predictive maintenance tools for optimizing plant efficiency and productivity, reducing unanticipated downtime and equipment failure, lowering maintenance costs while minimizing operational risks. Corrosion monitoring system is adopted in areas including transport pipeline, chemical injection system, flow line, vessels, drilling mud system, gathering system, water injection facilities where the probability of accidental risks are very high. Power generation sector is anticipated to be the fastest growing market with a CAGR 10.0% due to unprecedented upsurge in electricity supply accelerated by heavy industrialization and urbanization.<span lang="EN-GB" times="" new="" roman";mso-bidi-font-family:="" calibri;mso-bidi-theme-font:minor-latin;color:black;mso-ansi-language:en-gb;="" mso-fareast-language:en-gb"="" style="box-sizing: border-box;">

Corrosion Monitoring Market Segment Analysis – <span lang="EN-US" times="" new="" roman";mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;="" color:black;mso-themecolor:text1;background:white"="" style="box-sizing: border-box;">By Geography

By Geography, Corrosion Monitoring market is segmented under North America, Europe, APAC, South America and RoW. APAC dominated the market in 2020 acquiring a share of 36.5% and is estimated to account for the largest market share with the fastest growing CAGR 9.9% during the forecast period 2021-2026 owing to the emerging economy and rising investments towards maintenance and monitoring of ageing infrastructure to control accidental risks. South-east Asia is estimated to be the hot-zone for establishing manufacturing hubs during 2021-2026 and thus contributing to the growth of the market. In April 2021, China announced US$ 400 billion strategic and economic partnership agreement with China to strengthen petrochemical and oil & gas sectors. Such partnerships are anticipated to boost the market growth from 2021 to 2026.

Corrosion Monitoring Market Drivers

<span lang="EN-US" times="" new="" roman";mso-bidi-font-family:calibri;="" mso-bidi-theme-font:minor-latin;color:black;mso-themecolor:text1;border:none="" windowtext="" 1.0pt;="" mso-border-alt:none="" 0cm;padding:0cm"="" style="box-sizing: border-box;">Increasing demand for power generation

<span lang="EN-US" times="" new="" roman";mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;="" color:black;mso-themecolor:text1;border:none="" windowtext="" 1.0pt;mso-border-alt:="" none="" 0cm;padding:0cm;mso-bidi-font-weight:bold"="" style="box-sizing: border-box;">Increasing penetration of industry 4.0 and rapid urbanization have accelerated the demand for continuous electricity supply and thus boosting the market growth. Rising demand for continuous monitoring of aging infrastructure for optimizing electricity efficiency reducing losses has contributed to the growth of the market. The rapid technological advancements such as supervisory control and data acquisition (SCADA) systems with the rising developments of smart sensors is analyzed to significantly trigger the market growth<span lang="EN-US" times="" new="" roman";="" mso-fareast-theme-font:minor-fareast;mso-bidi-font-family:calibri;mso-bidi-theme-font:="" minor-latin;color:black;mso-themecolor:text1;background:white"="" style="box-sizing: border-box;">. In February 2021, Saudi Aramco Energy Ventures (SAEV) announced to invest $5 million in Corrosion RADAR Ltd., a UK based company to expand its predictive digital corrosion monitoring solution. Such investments are anticipated to boost the market during 2021-2026.

Rising awareness to mitigate corrosion related accidents in oil & gas industries

<span lang="EN-US" times="" new="" roman";mso-fareast-theme-font:minor-fareast;mso-bidi-font-family:="" calibri;mso-bidi-theme-font:minor-latin;color:black;mso-themecolor:text1;="" background:white"="" style="box-sizing: border-box;">Increasing demand for Corrosion Monitoring systems in oil & gas refineries to reduce or mitigate accidental risks due to pipelines or storage tank failure is driving the market. Increasing integration of IoTs with corrosion monitoring techniques to increase productivity reducing downtime has contributed to the growth of the market. Rising adoption of several sensor devices incorporated onto data acquisition system leveraging wireless communication to provide unisons among all associated systems for gathering real time in-situ information about components vulnerable to corrosion is propelling the growth of the market. For instance, in June 2020, KBC, in partnership with OLI Systems announced a predictive software solutions utilizing digital twin technology to provide real-time prediction of corrosion and scaling across oil & gas industry to enhance asset safety and profitability. Such developments are analyzed to steer the market between 2021 and 2026.

Corrosion Monitoring Market Challenges

<span lang="EN-US" times="" new="" roman";mso-fareast-theme-font:minor-fareast;="" mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;color:black;="" mso-themecolor:text1;background:white"="" style="box-sizing: border-box;">High Deployment and Maintenance Costs

<span lang="EN-US" times="" new="" roman";mso-fareast-theme-font:minor-fareast;mso-bidi-font-family:="" calibri;mso-bidi-theme-font:minor-latin;color:black;mso-themecolor:text1;="" background:white;mso-bidi-font-weight:bold"="" style="box-sizing: border-box;">The robustness and smart technology of Corrosion Monitoring solutions require high deployments and maintenance costs. Many small and medium enterprises are still reluctant to adopt this technology due to budget constraints. Furthermore, limited in-house capabilities and absence of skilled workforce lead to higher resolution time in case of technical glitches. However, these factors are anticipated to hamper the market growth during 2021-2026.

Corrosion Monitoring <span lang="EN-US" times="" new="" roman";mso-fareast-theme-font:minor-fareast;="" mso-bidi-font-family:calibri;mso-bidi-theme-font:minor-latin;color:black;="" mso-themecolor:text1;background:white"="" style="box-sizing: border-box;">Market Landscape

Technology launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players <span lang="EN-GB" calibri","sans-serif";="" mso-ascii-theme-font:minor-latin;mso-hansi-theme-font:minor-latin;mso-bidi-theme-font:="" minor-latin;color:black;mso-themecolor:text1"="" style="box-sizing: border-box;">in the Corrosion Monitoring market. In 2020, the market of Corrosion Monitoring industry outlook has been fragmented by several companies. Corrosion Monitoring top 10 companies include Intertek Group PLC, SGS S.A., Applied Corrosion Monitoring Ltd., BAC Corrosion Control Ltd., Parmasense Ltd., ICORR Technologies, Rysco Corrosion Services, Pyramid Technical Services, Corrpro Companies Inc., Korosi Specindo among others.

<span lang="EN-US" times="" new="" roman";mso-bidi-font-family:="" calibri;mso-bidi-theme-font:minor-latin;color:black;mso-themecolor:text1"="" style="box-sizing: border-box;">Acquisitions/Technology Launches

- <span lang="EN-US" times="" new="" roman";mso-bidi-font-family:="" calibri;mso-bidi-theme-font:minor-latin;color:black;mso-themecolor:text1"="" style="box-sizing: border-box;">In March 2021, Olympus unveiled new DC series transducers offering a complete corrosion monitoring toolbox for pipeline and tank integrity in oil & gas, energy and mining industries.

- In March 2021, Emerson introduced corrosion and erosion monitoring portfolio with digital capabilities to monitor the risk of corrosion or erosion in oil & gas processing.

Relevant Report Titles:

Inorganic Corrosion Inhibitors Market

Report Code: CMR 1066

Report Code: CMR 0067

For more Automation and Instrumentation Market reports, please click here