views

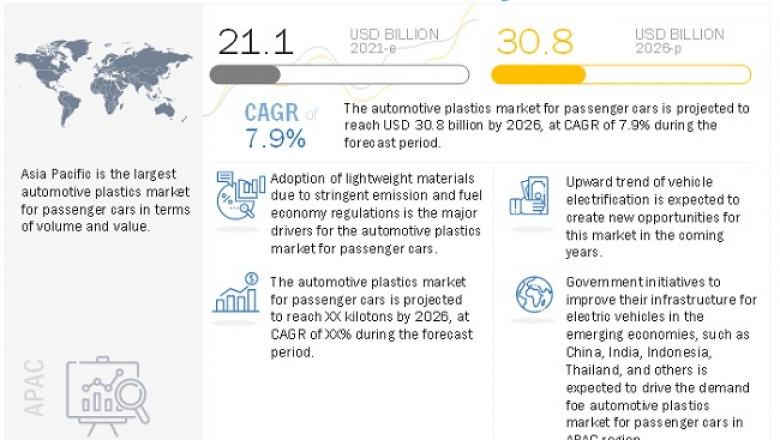

The global automotive plastics market for passenger cars size is projected to grow from USD 21.1 billion in 2021 and is projected to reach USD 30.8 billion by 2026, at a CAGR of 7.9%. The demand for automotive plastics is mainly driven by the increase in passenger car production and the increasing utilization of automotive plastics in vehicle designs. Plastics offer a maximum weight reduction of automobiles, which in turn reduces carbon emissions. These could be the major reasons propelling the market.

The shift towards use of bioplastics in vehicle production, use of anti-microbial plastics and additives, use of composites and PMMA and growing trend of vehicle electrification has increased the demand for automotive plastics across the globe. The development in 3D printing technology is expected to act as new opportunities for the automotive plastics market for passenger cars to grow. However, high cost of capital and infrastructure for re-engineering of plastics is expected to hinder the market growth during the forecasted period.

The under-bonnet is the fastest-growing application segment of the automotive plastics market for passenger cars during the forecast period. Automotive plastics used in the manufacturing of under-bonnet components of passenger cars include Polypropylene, PBT, polyamide, and other engineered plastics. The use of plastics in under-bonnet applications provides high durability, high-temperature resistance, strength, and rigidity to automobiles. The under-bonnet segment includes components such as the battery, onboard chargers, connectors, cables, electric motor, anti-lock braking system, hoses, hydraulic booster unit, load-sensing valve, master cylinder, metering valve, fuel delivery modules, intake manifolds, brackets, duck work, accumulator pistons pressure differential valve, proportioning valve, and thermal management system which require plastics in their manufacturing.

BASF SE (Germany), SABIC (Saudi Arabia), LyondellBasell Industries Holdings BV (Netherlands), LG Chem (South Korea), DuPont (US), Covestro AG (Germany), Evonik Industries AG (Germany), Solvay (Belgium), Arkema SA (France), Borealis AG (Austria), among others are the key players operating in the automotive plastics market for passenger cars.