views

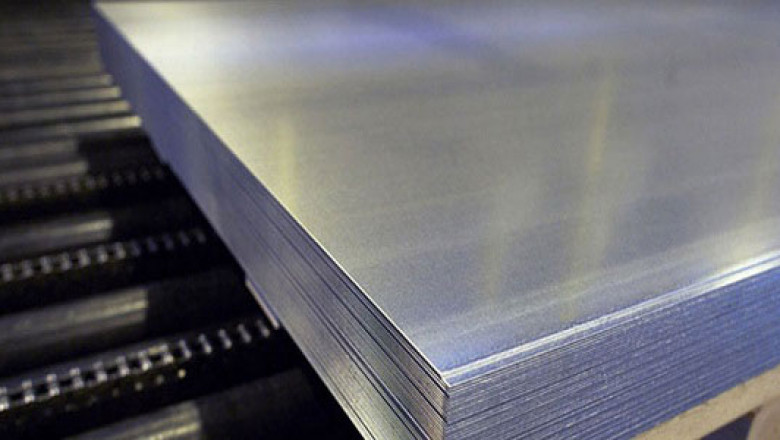

Stainless Steel 316ti Plate

Stainless Steel 316Ti Plate is a high-quality material that has good corrosion resistance and a uniform internal structure. Its advantages make it ideal for applications in electronics, boats, heat shields, and crucibles. The materials are available in different grades and can be produced through extrusion. Stainless Steel 316Ti Plates can be supplied in satin, matte, and as-rolled conditions.

Stainless Steel 316Ti Plate can be welded, and it shows excellent weldability, both without filler and with filler metals. Micro and macro-weldability tests are available for this material. Other test methods include pitting resistance, positive material identification, and hardness. Stainless Steel 316Ti plate is widely used in many industries, including construction and welding. The corrosion resistance and forming properties of 316Ti Plates are superior to those of other stainless steel.

Stainless Steel 316Ti Plates are the highest quality stainless steel plates available. Made of premium raw materials, these products are certified by quality experts nationally. These steel plates are made from austenitic stainless steel and exhibit superior resistance to corrosion and oxidation. Nickel, molybdenum, and chromium are among the alloy's components. The material's chemical makeup makes it a superior choice for applications in the marine industry.

Uses of 316Ti Plate

316Ti stainless steel plate 2B has a smooth surface and is typically cut to a specified size for a variety of uses. Its use ranges from hydrogen fuel cells to Marine applications. It is commonly required for corrosion resistance against acids and is widely used in construction, chemical, oil, and automotive industries. Some of its common uses are outlined below. The following is a list of some of the more common uses of 316Ti.

Stainless steel 316Ti plates are manufactured under strict quality controls and are tested against a number of different parameters. As a result, they meet the stringent specifications required for various applications. In addition, various types of quality tests, including PMI, third-party inspection, flaring tests, and other tests, are performed to ensure that the 316Ti plate meets international standards. Once manufactured, 316Ti stainless steel plate is packaged for shipment in pallets or wooden cases.

Stainless steel 316Ti is a stabilized variation of the austenitic chromium-nickel alloy 304. It is incorporated with molybdenum, which increases corrosion resistance. It is particularly resistant to acid sulfates and alkaline chlorides. However, this material is not suitable for continuous use in high temperatures. Because of its low carbon content, 316Ti is often preferred for a wide range of uses.