views

the WHO suggests the industry needs to increase chemical products by 40%

The COVID-19 pandemic is driving a worldwide interest in medical supplies, equipment and cleaners. When it comes to PPE alone, the WHO estimates that there's a global-wide monthly interest in 89 million medical masks, 76 million examination mitts and 1.six million goggles. To satisfy this demand, the WHO suggests the must increase chemical products by 40%. Caffeine market is rising to that particular challenge in multiple ways. From generating more chemicals, like reagents and solvents, from recycleables to switching production lines to create disinfectants or medical supplies, caffeine industry has proven creativeness to meet the requirements. But while answering the immediate crisis, it’s worth thinking about the more-term impact from the pandemic around the industry.

Caffeine Market is a vital Player in Tackling COVID-19

The medical, healthcare and pharmaceuticals sectors are key consumers of chemicals for example raw ingredients, refined reagents, solvents and handle products - and demand from customers has elevated dramatically because of the COVID-19 pandemic. Governments around the world have therefore identified caffeine industry like a critical infrastructure. Which means chemical industry personnel are maintaining normal work schedules associated with all chemical logistics activities, manufacture, production and transportation of recycleables or finished chemicals.

Chemicals Industry Materials sought after

The American Chemistry Council (ACC) have produced infographics explaining what chemical products lead to medical equipment, supplies and cleaners. When it comes to worth of input materials, chemicals lead:

75% of materials in cleaning compounds like detergents, disinfectants and hands sanitizers

27% of materials in medical equipment like N95 goggles, disposable gowns and diagnostic equipment

25% of materials in medical supplies like goggles, mitts, tubing and surgical instruments.

In addition to producing intermediary chemical products, for example solvents and reagents, many chemical information mill also producing final products and handle products.

Disinfectants and cleaners

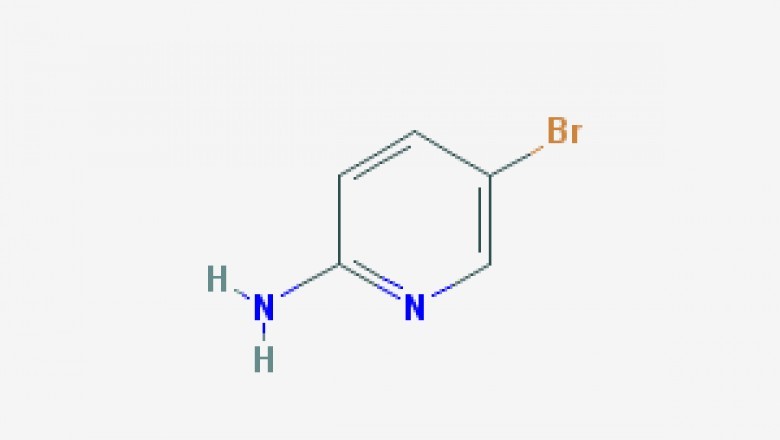

Various countries have reported logistics shortages from the ingredients utilized in disinfectants. Included in this are ethanol, propan-2-ol (isopropyl alcohol), benzyl chloride, ethylbenzyl chloride and methyl chloride. Many regulators have responded by providing derogations or regulatory waivers to permit manufacture of non-approved ingredients or products from non-approved suppliers. Caffeine industry has responded by expanding manufacture of ingredients and final products. Others also have pitched in, for instance liquor producers are actually manufacturing hands sanitizers or offering denatured alcohol to disinfectant makers.

See our blog on hands disinfectants to understand more about the modification in biocide regulatory approach in Europe.

PPE

PPE is crucial in barrier nursing, which is often used to handle patients with coronavirus infection to lessen multiplication of infection. The WHO provided guidance (March 19, 2020) on optimizing PPE use, with lots of countries supplying tailored public health guidance. The PPE needed whenever using a COVID-patient includes masks/respirators (N95 or FFP2 standard), gown (or apron), mitts and eye protection (goggles or face shield).

Surgical gowns are frequently built from synthetic fibers like polypropylene or polyethylene. Single use gowns are often produced from non-woven sheets made up of wood pulp and polyester. Mitts are usually produced from neoprene, polyisoprene or nitrile. Eye protection like safety visors can be created from polycarbonate, propionate, acetate, polyvinyl chloride or polyethylene terephthalate glycol (PETG).

PPE levels are running lower in many healthcare settings around the globe, with lots of industries, along with the chemical industry, answering demand.