views

PCBA burn-in test standard and PCBA burn-in test method

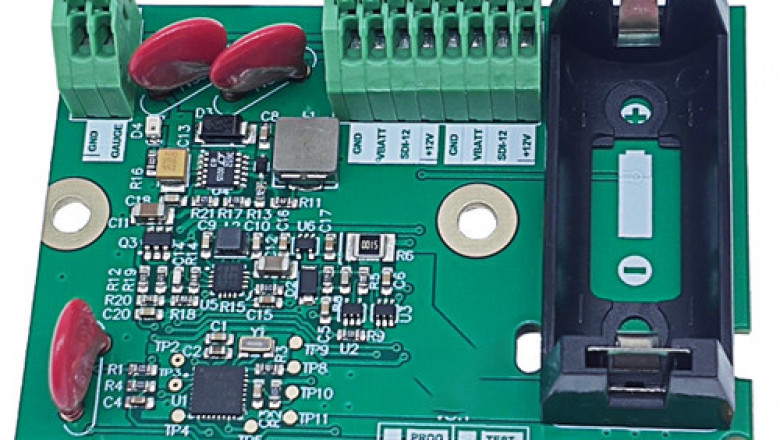

The main purpose of the PCBA board aging test is to simulate the daily use environment of the product through the combined effects of high temperature, low temperature, high and low temperature changes and electric power, and expose the defects of PCBA, such as poor soldering, mismatch of component parameters, and debugging process In order to eliminate and improve the caused failure, it will play a role in stabilizing the parameters of the non-defective PCB assembly board.

pcba aging test standard

1. Low temperature work

After placing the PCBA board at a temperature of -10±3°C for 1h, under this condition, the rated load should be carried. Under the conditions of 187V and 253V, all procedures should be powered on and the procedures should be correct.

2. High temperature work

After putting the PCBA board at 80±3℃/h, under this condition, with load, under the conditions of 187V and 253V, power on and run all the programs. The program should be correct.

3. High temperature and humidity work

Put the PCBA board at a temperature of 65±3°C and a humidity of 90-95% for 48 hours, and run the programs with the rated load. Each program should be correct.

PCBA aging test method

1. Put the PCBA board at ambient temperature into the heat aging equipment at the same temperature, and the PCBA board is in operation.

2. Reduce the temperature in the equipment to the specified temperature value at a specified rate. When the temperature in the equipment reaches a stable value, the PCBA board should be exposed to low temperature conditions for 2 hours.

3. Raise the temperature in the equipment to the specified temperature at a specified rate. When the temperature in the equipment is stable, the PCBA board should be exposed to high temperature conditions for 2 hours.

4. Reduce the temperature in the equipment to room temperature at a specified rate, continue to repeat until the specified aging time, and perform a measurement and record on the PCBA HDI PCB board according to the specified aging time.

POE provides customers with a one-stop service from hardware design, smart manufacturing to smart products, allowing you to save time and energy, production costs, and devote yourself to the development and sales of new products. And has R&D and design capabilities and product manufacturing capabilities, and is committed to quickly turning your needs into smart hardware.