views

Material handling is a crucial department in any manufacturing industry that involves the bulk movement of materials from one place to another which changing the nature of the materials. It is the most attractive and major areas where cost can be reduced. If labours are employed for moving such bulk materials, it involves cost and does not have enough safety for them. When the costs are reduced, it ultimately results in less cost for a finished good.

EOT (Electronic overhead travelling) crane is essential industrial equipment involved in material handling job. Overhead EOT single girder cranes are used to lift the objects by a hoist fitted in a trolley.It comes under standard crane types. Overhead cranes can be segregated under two categories based on the number of cross –girders and based on the nature of running.

- Based on the number of crosses- girders it can be categorized as single and double girder cranes.

- Based on the nature of running it can be top running and under running cranes.

EOT crane configuration has under running and top running cranes (based on nature of running).

Under running:

Running on the bottom flange of runway girders, the running cranes are supported from the roof structure. They are advantageous since the very small trolley approach dimension can utilize the maximum of the building's width and height. There is a possibility of using the existing ceiling girder for protecting the crane track.

Top running:

A girder is a support beam that is used to denote the main horizontal support of a structure that supports smaller beams. Single girder cranes can be of

- I-beam type main girder which has a crane span of 18m(59 ft) and loads up to 10 tonnes

- Box-type main girder which spans up to 30m (98 ft) and can uplift load up to 40 tonnes

- Under running single girder cranes which span up to 22m (72 ft) and weight lift load up to 12.5 tonnes.

Single girder cranes cost less in many ways as only cross girders are needed; quicker installation; runway beams are lighter enough due to reduced crane dead weight.

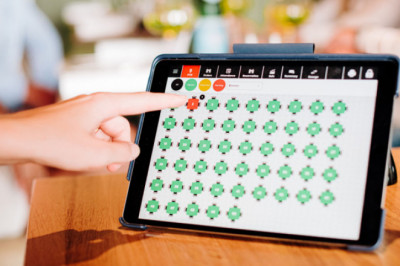

Overhead cranes can be controlled with radio remote controls or independent travelling push button pendants which allow operators to stand on the safe side and operate. Operators are in such a way of a safer side to have an obstacle less view for smooth functioning of operations.

The unique attributes of EOT cranes is underlying in the design optimization such that it avoids deadweight and reduces the cost of the equipment. It is mostly used in construction companies, manufacturing heavy equipment, exports of materials that cannot be handled with hands as such.