views

Predictive maintenance techniques are intended to help decide the state of in-administration hardware to assess when maintenance ought to be performed. This methodology guarantees cost reserve funds throughout routine or time sensitive preventive maintenance, since assignments are performed just when justified. Hence, it is viewed as condition-based maintenance completed as recommended by assessments of the debasement condition of a thing.

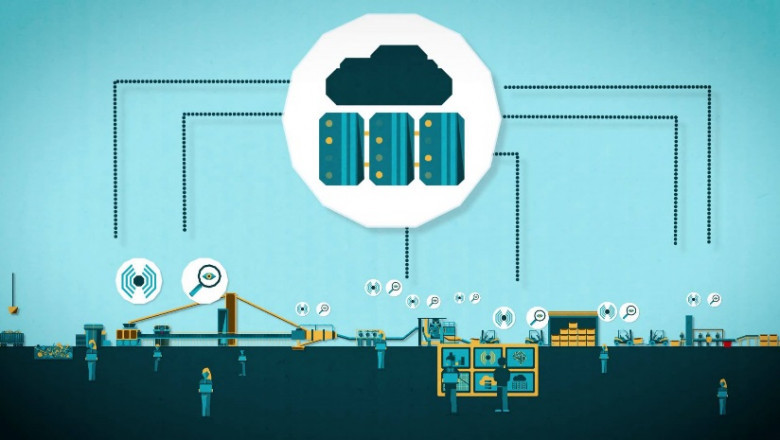

Operational predictive maintenance software recover numerous data sources continuously to anticipate quality issues or resource disappointment. Reception of these software solutions work with associations to forestall personal time and decrease maintenance costs. Operational predictive maintenance software solutions recognize disappointment examples and minor inconsistencies to decide the resources and operational cycles that are at the most serious danger of disappointment. Sending of activity predictive maintenance software helps gear uptime and upgrade inventory network cycles and quality. One of the central point for the expanding utilization of these software solutions is their capacity to precisely foresee resource disappointment, empowering undertakings to remove the resource from production resulting proficient inventory network.

Read More: https://bit.ly/3mRp5gE