views

Remote monitoring systems that are built with IoT help increase the efficiency and effectiveness of such industrial assets. The remote monitoring system helps track the processes in real-time, which ensures that there are fewer errors and unplanned downtime. IoT uses intelligent sensors to detect any sort of damage in the pipeline.

Let us look at how IoT helps manage the pain points in the system of maintaining and rectifying leaks in the oil and gas pipelines:

Real-Time Alert System

The IoT system enhances the company with a real-time alert system that provides instant notifications if there is a pipeline leak. This quick system ensures that the damage is communicated at an early stage which helps in curbing a lot of potential environmental hazards that can come up due to the seeping of the oil or gas into nature. The real-time data provided will predict accurate data that can be mitigated on time. The sensor technology encompassed by the IoT monitors various aspects of the liquid or gas flowing through the pipelines like temperature, pressure, compression, and other parameters. Infrared cameras can be sent into the pipeline, to spot the exact spot of the leak and can also help with providing the correct images of the smoke or leak. You can also put in fibre optic cables which can easily assess the temperature variations inside the pipeline.

Effective Monitoring System

Even a minute discrepancy in the pipeline can be studied effectively using IoT technology. The IoT sensors are equipped to detect real-time information on the pipelines; Each pipeline is tested from time to time and in case of an issue, a real-time message is sent to the operators so that they can do the needful to solve or rectify the issue. If the problem is at large, then they can call to shut down that particular pipeline till the time the damage is cleared.

Communication of real-time equipment status

IoT sensors formulated can bring in a more evolved idea of communicating the changes if the equipment has any problem. An effective administration of oil and gas can only be possible if there is consistency in the operations. The IoT sensors help in monitoring and keeping track of any excessive vibrations or pressure build-up. Not having access to this information might result in a bigger loss. The IoT solutions help in detecting pressure changes, emissions, pulses, etc.

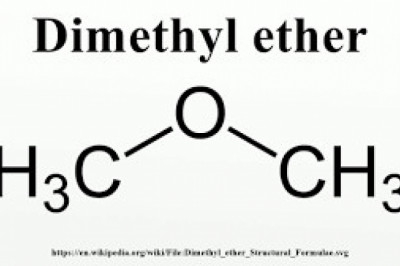

Gas Detection

The IoT sensors are formulated to detect gases like methane. They have deliberately channeled even to detect minute quantities of combustible gases. If not monitored efficiently, it can result in hazardous explosions. A powerful IoT solution will be able to keep a check on any undue influence irrespective of their size and can improve efficiency thereby reducing the costs.

Better Lifespan of Assets

The remote monitoring of the oil and gas pipelines helps avoid major problems before it even takes place. It can help focus on the better maintenance of the assets of the company; Well-maintained and managed assets or equipment will have better sturdiness and stability and will stand for a longer period of time. It also gives prompt notices when a part has to be replaced which can reduce the wear and tear considerably.

Better Visibility

Real-time information can help bring down better visibility of the processes inside the manufacturing department. The health of the machines and working system details are readily available to the respective managers, which makes the process transparent and area to take immediate decisions to rectify the problems.

Better Production Output

IoT technology aids in bringing a report very quickly. It ensures that any-machine related wear and tear and disruptions caused because of that are conveyed to production supervisors which helps in increasing the productivity of the unit. Spontaneous rectification of errors brings about effective strategies which help increase the business output.

The best thing a company can do is to select an IoT platform that is able to provide the best and most encompassed solution. It is quite an unsystematic process to depend on different platforms for the provision of different IoT services. Adapting to an IoT platform can also give you transparency on how your pipelines work and help maintain them intact for a longer period.