views

Which types of Polymer Grades are used in manufacturing of BOPP film and CPP film?

Polypropylene, sometimes known as PP, is a cost-effective Thermoplastic with excellent tensile strength, clarity, and gloss. Because it has a greater melting point than PE, it can be used in applications requiring high-temperature sterilization. It also has a greater gloss and less haze.

PP is metallized, its gas barrier qualities increase, making it suitable for demanding applications with a crucial product shelf life. PP films are, therefore, ideal for a range of industrial, consumer, and automotive applications.

PP is completely recyclable and is easily recycled into a variety of various products for a variety of uses. PP is not biodegradable, unlike paper and other cellulose-based goods. PP waste doesn't generate any poisonous or dangerous by-products.

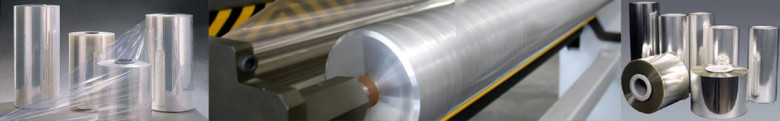

The two most effective forms are cast-oriented polypropylene (CPP) and biaxially oriented polypropylene (BOPP). Both kinds have great optics, a high gloss, good to excellent heat-sealing ability, better heat resistance than PE, and good moisture barrier qualities. Paragon poly is the best BOPP and CPP film suppliers.

Cast Polypropylene Films (CPP film suppliers)

Compared to biaxially orient polypropylene, cast-oriented polypropylene (CPP) has fewer applications than BOPP. In many conventional flexible packaging and non-packaging applications, CPP has been progressively gaining ground as a great option. To fulfil certain packaging, performance, and processing needs, the film's characteristics can be altered.

Compared to BOPP, CPP exhibits greater heat-sealing, cold-temperature performance, and rip and impact resistance.

Biaxially Oriented Polypropylene Films (BOPP)

A crucial type of polypropylene film is biaxially oriented polypropylene. It is an excellent substitute for aluminium foil, waxed paper, and cellophane. The orientation enhances optical characteristics, lowers elongation (harder to stretch), boosts tensile strength and stiffness, and somewhat improves vapour barrier qualities. As a result, BOPP outperforms CPP in terms of tensile strength, modulus (stiffness), elongation, more substantial gas barrier, and haze.

Below are some distinctions between CPP and BOPP for your understanding:

· BOPP is rigid and crinkly, whereas CPP is soft, film-like polythene.

· Due to its natural live hinge, CPP does not dead-fold well, but BOPP has better dead-fold properties.

· CPP may be thermally or ultrasonically sealed with no specialised coatings, but BOPP struggles to heat seal without such special coatings.

· Although CPP films have more excellent barrier qualities than most other polythene and PVC films, BOPP films offer superior barrier qualities.

Both CPP and BOPP is a type of PP and it has been used in various applications with great benefits and properties provided by paragon poly. They are the leading BOPP and CPP film suppliers.