views

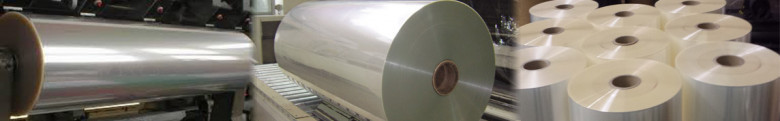

What is the Introduction BOPP film overview?

Biaxially Oriented Polypropylene Film is referred to as BOPP Film (BOPP film suppliers). It is made by stretching polypropylene film longitudinally and transversely before being extruded from plastic granulates (polypropylene). The molecular structure's altered shape gives the films a range of beneficial characteristics, including transparency, toughness, and other attributes.

It has many applications, including packaging, labelling, and laminating. The best chance of the pack being a monolayer/homogeneous structure is provided by BOPP Films, which are the preferred substrate for food packaging because of their inherent moisture barrier features, seal ability, excellent clarity, and graphic reproduction. It is frequently used as a co-extruded heat-sealable reverse-printed film for food packaging. Due to its yield advantage (lowest density of 0.55 for IML orange peel effect) and compatibility with PP containers, BOPP Films are chosen for labelling because of their high demand worldwide. Paragon poly is one of the leading BOPP film suppliers because of the tensile strength of the film which is made used in a lot of industries.

There are various benefits that BOPP provides:

Increased shelf life: Among all other regularly used plastic films, BOPP films offer the product's best moisture and oxygen barriers, and their metallized version is even better. These two characteristics of BOPP films are essential for food packaging to increase product shelf life and decrease food waste.

Product quality: BOPP film suppliers offer exceptional seal integrity and barrier capabilities because of its low gauge spread. The food packaging business also gains from good heat seal strength, lower seal initiation temperature, a broad ceiling window, and good machinability by preserving food quality.

Sustainability: BOPP film has a relatively small carbon footprint compared to other plastic film substrates, including polyester. Due to its eco-friendliness in flexible food packaging, BOPP Film is the second most favoured substrate after cellulose film. Low melting point materials require less energy to change from one form to another. Reprocessed BOPP resin granules are frequently used to create injection-moulded components and home goods such as seat mats, chairs, tables, and vehicle parts.

Aesthetic/ Graphics: Excellent transparency in explicit BOPP films gives product packaging an appealing look. This film also makes it simple to print high-quality artwork in halftone with many colours. Perfect gloss, high opacity, and outstanding whiteness make the white opaque film type an ideal choice for product packaging. The metallised film variant's superb metallic appearance makes your goods stand out in the store. Post-lamination processes, including foil stamping, UV spot coating, and embossing, could improve the aesthetic appeal of product packaging because of the material's good surface tension.

Density: Compared to other regularly used flexible packaging films, BOPP films have a unique quality. Low density promotes using less plastic per product by increasing yield

during conversion. In addition, low-density plastic films weigh less per roll for a length than conventional plastic films, making it simpler to handle the materials.